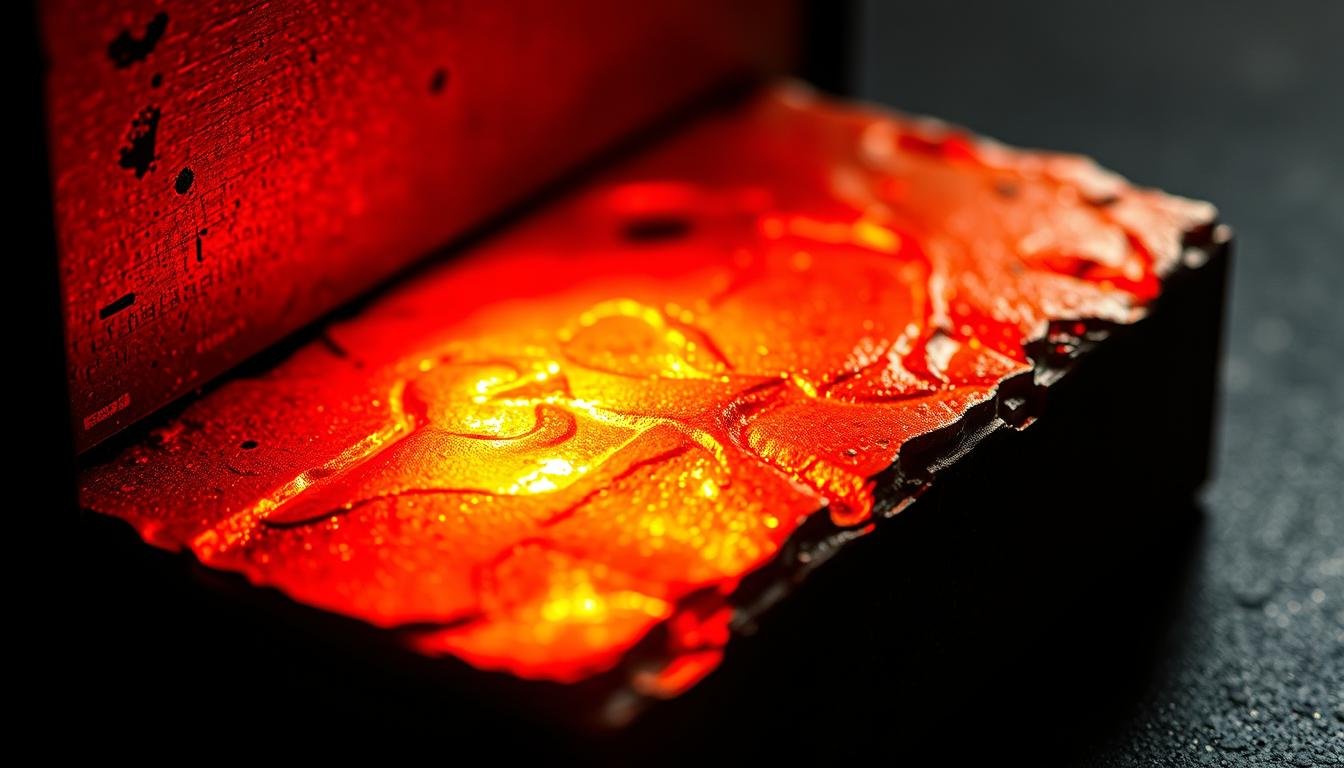

What makes certain materials thrive in extreme heat while others fail? The answer lies in atomic structure and unique physical properties. One metallic element stands unmatched in high-temperature performance, earning its place as the ultimate refractory metal for industrial and scientific applications.

With an atomic number of 74 and symbol W, this remarkable element demonstrates extraordinary thermal resilience. It maintains structural integrity at temperatures exceeding 3,400°C (6,150°F) – hotter than volcanic lava flows. These characteristics make it indispensable for spacecraft components, advanced electronics, and high-performance manufacturing systems.

The secret to its endurance lies in two critical factors: atomic bonding strength and thermal expansion resistance. Unlike common metals that weaken dramatically when heated, this material retains over 85% of its room-temperature strength at 1,650°C (3,002°F). Its minimal expansion under thermal stress prevents warping in precision instruments.

Modern industries rely on these properties for cutting-edge technologies. From rocket engine nozzles to radiation shielding, the element’s stability under extreme conditions enables breakthroughs in aerospace engineering and energy production. This introduction explores how its fundamental characteristics translate into real-world solutions for temperature-critical applications.

Introduction to Tungsten and Its Remarkable Properties

Spanish chemists Juan José and Fausto Elhuyar made history in 1783 by isolating a revolutionary grayish metallic element from wolframite ore. Their charcoal reduction technique for tungsten oxide (WO3) unlocked what would become a cornerstone of modern engineering.

From Laboratory Curiosity to Industrial Powerhouse

Initially brittle and challenging to work with, this material revealed hidden potential when heated. Through mechanical processing at extreme heat, it transforms into ductile wires thinner than human hair. This adaptability fueled its adoption in early incandescent lighting and wartime armor-piercing rounds.

Defying Thermal Limitations

What sets this element apart is its unmatched performance where others falter. Unlike common metals that deform under stress, it maintains structural integrity at temperatures exceeding 3,000°F. These traits make it vital for:

- Spacecraft heat shields facing atmospheric re-entry

- Nuclear reactor components enduring constant radiation

- Industrial cutting tools operating at peak efficiency

Modern metallurgists continue pushing boundaries, developing tungsten alloys that combine durability with unprecedented heat resistance. This evolution ensures its position as the material of choice for next-generation aerospace and energy technologies.

Understanding Tungsten’s Physical and Chemical Attributes

At the heart of this remarkable material lies an atomic structure that defies conventional limitations. With 74 protons in its nucleus, the element known chemically as W ranks among the densest naturally occurring substances on Earth.

Atomic Foundations and Material Density

Boasting an atomic weight of 183.85, this transition metal in the periodic table achieves a staggering density of 19.3 g/cm³. To put this in perspective:

- Surpasses lead by 70% in mass-volume ratio

- Nears uranium’s density without radioactive properties

- Maintains structural compactness even at atomic scale

Conductivity Characteristics

The material’s electron configuration [Xe]4f¹⁴5d⁴6s² enables exceptional energy transfer capabilities. Its thermal conductivity reaches 173 W/(m·K), outperforming many common alloys. Electrical flow efficiency remains stable across temperature extremes – a critical feature for aerospace circuitry.

Six oxidation states (+2 to +6) provide versatile bonding potential, while maintaining corrosion resistance in harsh environments. These combined traits make the metal indispensable for applications requiring simultaneous thermal management and electrical precision.

The Science Behind a High Melting Point

Atomic bonds and structural configurations determine a material’s ability to withstand blistering temperatures. Elements with exceptional thermal resistance achieve this through complex interactions at the subatomic level.

These interactions create a robust framework that resists deformation even under intense heat. Scientists attribute this phenomenon to two primary factors: electron behavior and lattice stability.

Strong Metallic Bonding and Atomic Structure

The foundation of thermal endurance lies in electron behavior and lattice arrangement. A body-centered cubic (BCC) configuration maximizes atomic coordination, allowing efficient electron sharing between atoms.

This creates a dense network where d-orbitals overlap significantly, enhancing bond strength. Such structural efficiency contributes to a high melting point, allowing materials to remain solid at temperatures exceeding 3,000°F.

Role of Cohesive Energy and Thermodynamic Stability

Cohesive energy measures how tightly atoms bind within a material. Higher values indicate stronger interatomic forces, directly influencing melting points—the critical temperatures where solids transition to liquids.

Materials with elevated cohesive energy require more thermal input to break atomic bonds and initiate phase changes. This principle explains why certain substances maintain integrity under extreme conditions.

Thermodynamic stability ensures structural integrity across temperature extremes. Stable lattice configurations minimize energy loss during heating, preventing premature breakdown.

This combination of factors explains why tungsten’s melting characteristics enable stability in environments where other metals fail. Industrial applications leverage these properties for components exposed to sustained high heat.

Historical Discoveries and Key Innovators in Tungsten Research

Scientific progress often hinges on collaborative breakthroughs. In 1781, Carl Wilhelm Scheele identified tungstic acid while studying scheelite. This discovery paved the way for Spanish chemists Juan José and Fausto Elhuyar to isolate the pure metallic element two years later through charcoal reduction.

Contributions from Fausto Elhuyar and Irving Langmuir

The Elhuyar brothers developed a revolutionary method using tungsten oxide and carbon. Their technique enabled the first reliable production of metallic samples. A century later, Irving Langmuir transformed these findings into practical applications through vacuum tube innovations.

Langmuir’s work with General Electric produced durable filaments for incandescent bulbs. His colleague William Coolidge later perfected tungsten wire drawing. These advancements made mass-produced lighting systems possible.

The Evolution of Processing Techniques

Early refinement methods relied on basic smelting and forging. Modern approaches employ advanced powder metallurgy for superior results. This shift allowed manufacturers to create complex components for aerospace and electronics.

| Time Period | Technique | Impact |

|---|---|---|

| 18th Century | Charcoal Reduction | Initial isolation |

| Early 1900s | Wire Drawing | Lighting revolution |

| 21st Century | Additive Manufacturing | Precision components |

Today’s materials scientists continue refining these processes. Their work ensures tungsten remains vital for cutting-edge technologies while honoring its rich scientific legacy.

Extraction and Occurrence of Tungsten Ores

The journey from raw mineral to industrial-grade metal begins deep within geological formations. This critical element bonds with oxygen and metals in nature, forming compounds that require specialized extraction methods. Two minerals dominate commercial operations due to their high metal content and relative abundance.

Major Ores: Wolframite and Scheelite

Wolframite and scheelite serve as primary sources for industrial applications. Wolframite forms dark, heavy crystals containing iron manganese tungstate (Fe,Mn)WO4. Scheelite appears as lighter-colored calcium tungstate (CaWO4) deposits, often fluorescing under UV light.

- Granite pegmatites near mountain ranges

- Hydrothermal veins with quartz deposits

- Skarn formations at limestone contacts

Global Production Insights and Mining Methods

China controls over 80% of worldwide output, with significant reserves in Jiangxi and Hunan provinces. Other key producers employ both surface and underground techniques:

| Country | Production Share | Primary Method |

|---|---|---|

| Vietnam | 7% | Open-pit mining |

| Russia | 5% | Underground blasting |

| Canada | 3% | Gravity separation |

Modern recovery processes combine crushing, magnetic separation, and chemical leaching. Environmental regulations now drive innovations in tailings management and energy-efficient refining. These advances ensure stable materials supply while reducing ecological impacts across mining regions.

Tungsten in the Periodic Table: Position and Comparisons

The periodic table serves as a roadmap for understanding elemental relationships. Group 6 transition metals share unique traits, but one member dominates high-temperature applications through its exceptional properties.

Refractory Metal Showdown

Four elements define the refractory metals category. Their performance under extreme heat determines industrial viability:

| Element | Density (g/cm³) | Thermal Conductivity | Key Applications |

|---|---|---|---|

| W | 19.3 | 173 W/m·K | Rocket nozzles |

| Mo | 10.2 | 138 W/m·K | Aerospace alloys |

| Ta | 16.6 | 57 W/m·K | Medical implants |

| Nb | 8.57 | 54 W/m·K | Superconductors |

This comparison reveals why Group 6’s heaviest member outperforms rivals. Its electron configuration ([Xe]4f¹⁴5d⁴6s²) enables superior atomic bonding strength. Five stable isotopes ensure consistent material behavior across temperature extremes.

Industrial engineers prioritize this element when designing components requiring:

- Radiation shielding in nuclear reactors

- Precision electrical contacts

- High-stress furnace parts

With abundance matching tin, this transition metal remains crucial for advanced technologies. Its position in the periodic table explains both capabilities and limitations, guiding material selection in extreme environments.

Processing and Melting Techniques for Tungsten

Manufacturing components from this refractory metal requires overcoming extreme thermal demands. Engineers combine advanced physics with precision engineering to transform raw ore into usable materials.

Advanced Melting Technologies and Challenges

Modern facilities use three cutting-edge methods to handle extreme thermal requirements:

- Plasma arc systems generating 20,000°C+ ionization zones

- Electron beam melters operating in vacuum chambers

- Induction heaters with magnetic field containment

These systems maintain inert atmospheres to prevent oxidation. Even brief oxygen exposure ruins material quality. Temperature sensors must withstand radiant heat exceeding surface temperatures on Venus.

Specialized Equipment for High-Temperature Processing

Production facilities feature custom-built components unseen in other metalworking plants. Graphite crucibles line water-cooled copper chambers, while robotic arms handle materials using ceramic grippers. Critical systems include:

| Equipment | Function | Operating Range |

|---|---|---|

| Hot isostatic presses | Densify powdered forms | 1,500°C |

| Swaging machines | Shape heated billets | 1,200-1,800°C |

| Chemical vapor deposition | Create protective coatings | 800-1,100°C |

These thermal processing methods enable cost-effective production of complex parts. Recent advances in additive manufacturing now allow 3D-printed components for aerospace systems.

High-Temperature Applications of Tungsten

How do industries harness materials that endure extreme environments? The answer lies in specialized elements that maintain functionality when ordinary substances fail. This section explores critical uses where thermal resilience determines operational success.

Illuminating Innovations and Thermal Management

Incandescent lighting revolutionized modern life through one key component. Filaments within bulbs glow white-hot without breaking down, enabling consistent light output. This durability stems from exceptional thermal stability at 2,500°C+ operating conditions.

Industrial heating systems benefit similarly. High-performance furnaces employ components that:

- Resist warping during repeated thermal cycles

- Maintain electrical conductivity under stress

- Withstand corrosive atmospheres

These properties make the material ideal for thermionic emitters in electron microscopes and electrical contacts in power grids.

Frontiers of Flight and Defense Systems

Rocket science demands materials that laugh at atmospheric friction. Nozzle throats in propulsion systems face temperatures exceeding 3,000°C during launch. Only one element provides the necessary combination of strength and heat resistance.

| Application | Temperature Range | Key Benefit |

|---|---|---|

| Reentry vehicle shields | 1,650-2,750°C | Ablation resistance |

| Hypersonic missile parts | 2,200°C+ | Structural integrity |

| Satellite thrusters | 1,800-2,400°C | Oxidation prevention |

Defense contractors increasingly rely on this element for radar systems and armor-piercing munitions. Its unique capabilities continue to enable breakthroughs in aerospace engineering and national security technologies.

Tungsten Melting Point: Applications and Implications

Modern engineering feats rely on materials that laugh in the face of extreme heat. The element with the highest melting point among metals unlocks possibilities where others falter, enabling technologies that push human innovation to new frontiers.

Powering Industrial Innovation Through Thermal Resilience

Rocket nozzles withstand 3,400°C+ temperatures during liftoff thanks to this material’s stability. Nuclear reactors use it for control rods that manage fission reactions without degrading. These applications highlight how thermal limits define industrial progress.

Cutting tools embedded with tungsten carbide maintain sharpness 10x longer than steel alternatives. Semiconductor manufacturers rely on its heat resistance for furnace components critical to chip production. Every sector benefits from its refusal to soften or warp under stress.

As industries pursue greener energy solutions, this metal’s role expands. Fusion reactor designs incorporate it to contain plasma hotter than the sun’s core. Its unique properties ensure tomorrow’s breakthroughs will be built on today’s most durable foundation.