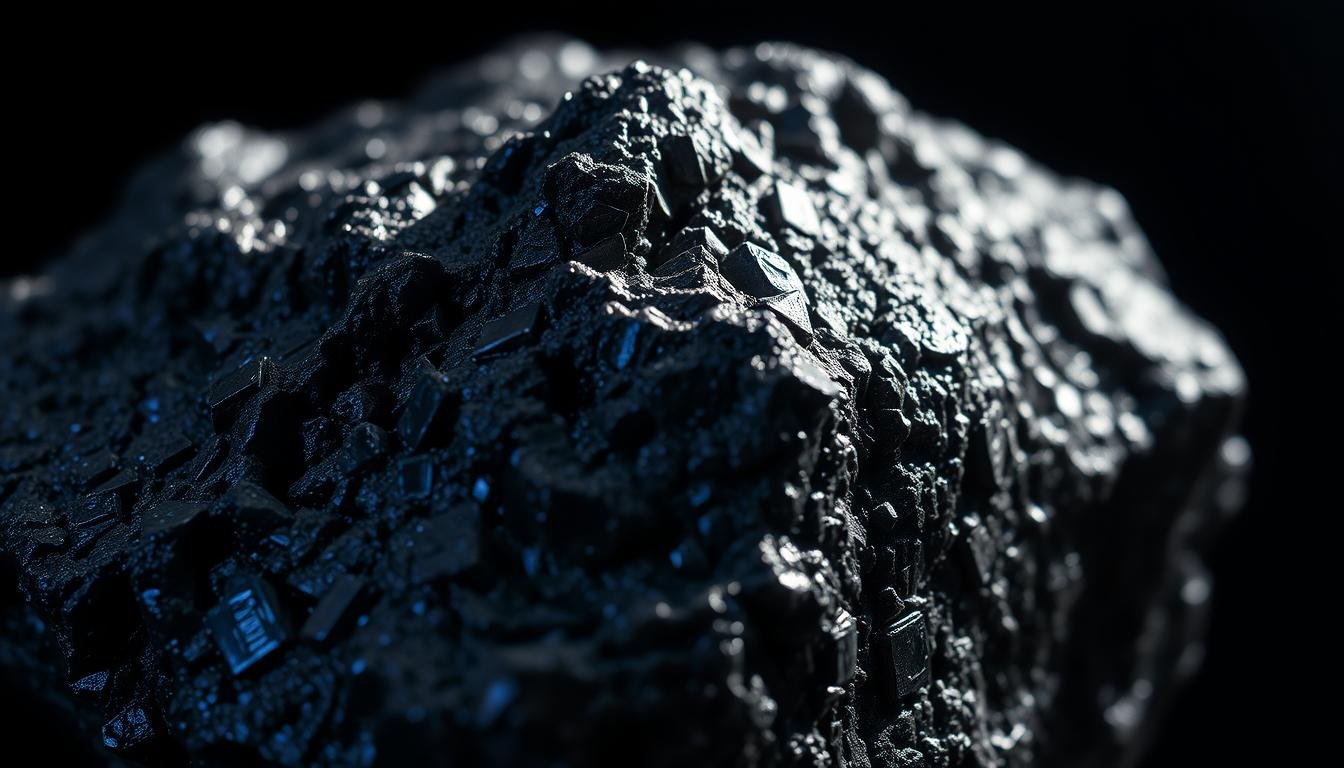

Tungsten is a remarkable metal known for its extraordinary density. It’s a key material in many advanced applications. With a density of about 19.25 g/cm³, it’s one of the densest naturally occurring elements.

It even beats metals like lead and gold in density. This article will dive into tungsten’s unique properties. We’ll see how its density affects its strength and versatility in fields like aerospace, medicine, and the military.

Knowing about tungsten density helps us understand its importance in today’s science and technology.

Understanding Tungsten’s High Density

Tungsten’s density is key to its many uses. Its atoms are packed tightly, making it one of the heaviest metals. With an average atomic mass of 183.84 amu, it’s clear why it’s so heavy.

The nucleus of tungsten has many protons and neutrons. This adds to its weight. This makes tungsten very useful in many fields.

Atomic Structure and Mass

The atomic structure of tungsten is body-centered cubic (BCC). This arrangement helps pack atoms tightly. It reduces voids, making the material denser.

The high atomic mass of tungsten also adds to its heaviness. Each atom’s weight makes it compact and useful in many ways.

Factors Contributing to Density

Several factors make tungsten a dense metal. Its BCC lattice structure is efficient. It allows atoms to cluster, making the metal durable and resilient.

This is important in high-stress environments. Tungsten’s density is higher than many other metals. For more on tungsten’s density, check this resource.

| Material | Density (g/cm³) | Atomic Mass (amu) |

|---|---|---|

| Tungsten | 19.3 | 183.84 |

| Lead | 11.35 | 207.2 |

| Iron | 7.87 | 55.85 |

Understanding tungsten’s atomic structure and density shows its amazing uses. These insights highlight its role in cutting-edge technology and industry.

What Makes Tungsten So Dense?

Tungsten’s high density comes from its atomic structure and how its atoms are arranged. It has 74 protons in its nucleus, which makes it very heavy. This heaviness makes tungsten one of the densest elements around.

Atomic Number and Nucleus Composition

The atomic number 74 of tungsten is key to understanding its density. More protons and neutrons in the nucleus mean a higher atomic weight. This is why tungsten is so dense, making it a valuable metal for many uses.

Body-Centered Cubic Crystal Structure

Tungsten has a body-centered cubic (BCC) crystal structure. This structure is important for its physical properties. Even though it’s not the densest, it packs tungsten atoms tightly and strongly.

This mix of high atomic mass and efficient arrangement makes tungsten perfect for tough industrial tasks.

Tungsten Density Compared to Other Metals

Tungsten is special among heavy metals, thanks to its density. It’s compared to lead, uranium, and gold. A detailed look shows tungsten stands out in many uses.

Tungsten Vs. Lead

The tungsten vs lead comparison is quite striking. Tungsten has a density of about 19.3 g/cm³. This is much higher than lead’s 11.34 g/cm³. This big difference shows tungsten’s heavy mass.

It’s great for places where space and weight matter a lot. Tungsten is perfect for aerospace and military tech. It’s strong and doesn’t take up much space.

Comparison with Uranium and Gold

Tungsten also shines when compared to uranium and gold. The tungsten density comparison shows it’s a top choice. Each metal has its own uses, but tungsten’s density makes it the best for many needs.

Applications of Tungsten Due to Its Density

Tungsten’s high density makes it valuable in many fields. It’s used in aerospace, medical technology, and more. Its unique properties help solve complex problems, ensuring safety and precision.

Aerospace Engineering

In aerospace, tungsten is key for stability. It’s used as counterweights in planes, improving safety and performance. It also helps in vibration dampening, making aerial parts last longer.

Medical Equipment Manufacturing

In medicine, tungsten is vital for shielding against radiation. It protects people from harmful X-rays and CT scans. Its density makes it a top choice for medical equipment makers.

Military and Defense Uses

In the military, tungsten’s density is a game-changer. It’s used in ammunition to pierce through armor. This makes military technology safer and more effective.

Tungsten Density in Metallurgy

Tungsten is key in metallurgy, thanks to its high density and special properties. These traits help advance many applications. In material science, knowing these properties is vital for making the best components.

As industries look for materials that are strong yet light, tungsten shines. It has amazing qualities that set it apart.

Importance in Material Science

In material science, tungsten’s density is very important. It decides if the material is good for many uses. Its strength-to-weight ratio is unmatched, leading to new ideas in many fields.

Adding tungsten to alloys makes them last longer. This is great for places with a lot of stress, like aerospace and the military.

Balancing Weight and Strength

Finding the right balance between weight and strength is key. Tungsten’s high density helps it be strong while taking up less space. This makes structures stronger without adding too much weight.

This special ability makes tungsten a top pick for where performance matters most.

How does Tungsten Density Affect Its Mechanical Properties?

The high density of tungsten greatly affects its mechanical properties. This includes tungsten hardness and tensile strength. Tungsten is known for being very hard, with a hardness of about 7.5 on the Mohs scale.

This hardness makes tungsten perfect for high-stress applications. It’s used in many industries because of this.

Hardness and Tensile Strength

Tungsten has an impressive tensile strength, often over 1200 MPa. This means it can handle extreme forces without breaking. It’s a top choice for military and aerospace needs.

Its density helps tungsten be tough and durable. For more on this, check out this resource on tungsten density.

Impact on Melting Point

The melting point of tungsten is very high, at 3,422°C (6,192°F). This keeps tungsten strong even in very hot conditions. It’s great for industrial uses where materials need to handle high temperatures.

Its ability to stay stable in heat makes tungsten very valuable. It’s essential for tasks needing both strength and stability.

How Pure Tungsten Compares to Other Metals

Pure tungsten is known for its unique properties, making it a key player in the world of heavy metals. Its density is much higher than many other metals, which is a big plus. This high density means tungsten is not only heavy but also very strong.

Density Metrics

Pure tungsten has a density of about 19.25 g/cm³. This is much higher than many metals used in industry. Here’s a table showing how tungsten compares to other metals:

| Metal | Density (g/cm³) |

|---|---|

| Pure Tungsten | 19.25 |

| Lead | 11.34 |

| Gold | 19.32 |

| Platinum | 21.45 |

| Iron | 7.87 |

| Aluminum | 2.70 |

Comparative Melting Points

The melting point of a metal is very important. Pure tungsten has a melting point of 3,422°C, the highest among all metals. This is much higher than metals like copper, steel, and lead.

This high melting point makes tungsten perfect for extreme temperatures. It’s why it’s chosen for tough jobs.

The Role of Tungsten Alloys in Industrial Applications

Tungsten alloys, like tungsten carbide, play key roles in many industries. They are known for their hardness and strength. These qualities make them essential for many manufacturing tasks.

Uses of Tungsten Carbide

Tungsten carbide is used in mining, construction, and manufacturing. Its hardness, almost 9 on the Mohs scale, is perfect for tools that wear out fast. It’s used for:

- Cutting tools

- Drill bits

- Industrial machinery components

- Wear-resistant coatings

Corrosion Resistance and Durability

Tungsten alloys are durable and resistant to corrosion. This makes them great for tough environments. They last longer, saving on maintenance and boosting efficiency.

| Property | Tungsten Carbide | Steel | Iron |

|---|---|---|---|

| Hardness | 9 | 5-8 | 4-6 |

| Corrosion Resistance | Excellent | Moderate | Poor |

| Tensile Strength (psi) | 300,000 | 150,000 | 75,000 |

| Typical Uses | Cutting Tools, Mining Bits | Construction, Automotive | Basic Tools, Hardware |

In summary, tungsten alloys and tungsten carbide improve performance and last long. They are key in industries for their durability and strength. Their properties make them a top choice in many fields.

Manufacturing Techniques Influenced by Tungsten Density

Tungsten density is key in many manufacturing methods, like tungsten powder metallurgy. Its high melting point and strength make it great for making precise parts. In tungsten powder metallurgy, sintering helps particles stick together tightly. This makes parts very dense and strong.

Advances in additive manufacturing are changing how we make tungsten parts. With 3D printing, we can now make complex shapes easily. Using tungsten powders, makers can create better designs faster and with less waste. This mix of tungsten density and new manufacturing ways opens up new uses in many fields.

The growth of tungsten fabrication, mainly in additive manufacturing, shows a lot of promise. With special tools and methods, even hard shapes can be made exactly. As more industries use these new ways, the use of tungsten powder metallurgy will likely grow more.

For more on these methods, check out this resource. It shows how these changes affect tungsten’s uses.

Conclusion

The importance of tungsten in today’s world is huge. Its high density and strong mechanical properties make it key in many fields. It’s used in aerospace and medical equipment, showing its strength in harsh conditions.

This look at tungsten’s properties shows its big role in today’s tech. As science moves forward, tungsten’s special qualities will keep pushing innovation. It will stay important in many areas for years.

Learning about tungsten’s density helps us see how amazing it is. It encourages us to find more ways to use it. This makes it clear that tungsten is a critical resource for tech and industry growth.