Certain elements stand unmatched when exposed to extreme heat. Among them, tungsten leads with a staggering heat tolerance of 3,422°C—enough to remain solid in environments where most materials disintegrate. Close behind are rhenium and tantalum, two other rare substances capable of enduring temperatures above 2,966°C. These extraordinary materials belong to a specialized class called refractory metals, defined by their ability to retain structural integrity under intense thermal stress.

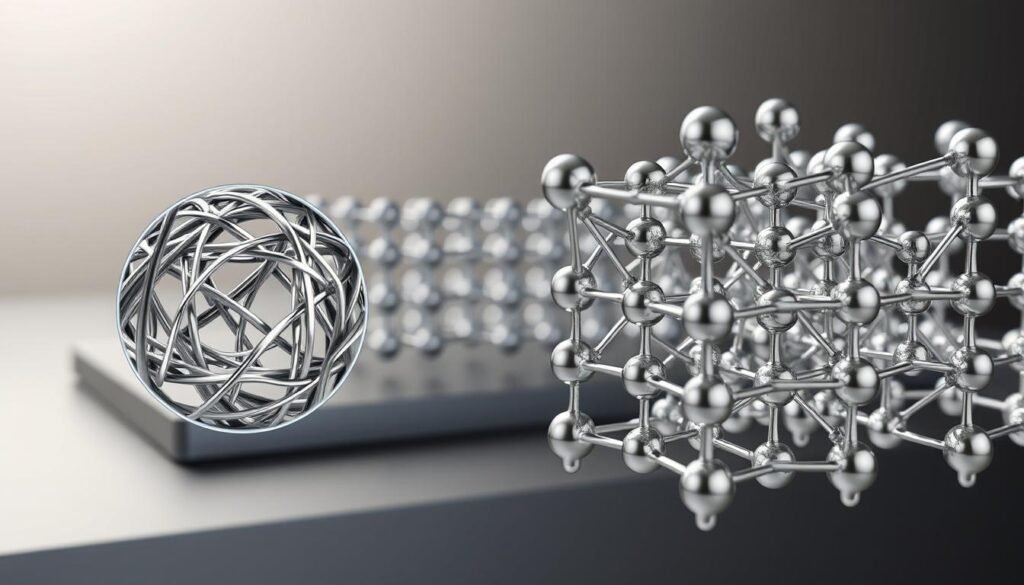

What makes these substances so resilient? Their strength lies in dense atomic structures and robust metallic bonds. Electrons in these elements form tight networks, creating a barrier against heat-induced breakdown. This unique combination allows them to excel in applications like rocket engines, nuclear reactors, and advanced electronics.

Industrial demand for such materials continues to grow. Aerospace engineers rely on their thermal stability for turbine blades, while semiconductor manufacturers use them in circuitry exposed to high-energy processes. Even everyday technologies like smartphone components benefit from their heat-resistant properties.

This guide explores the science behind these remarkable elements, their real-world uses, and how engineers choose the right material for extreme conditions. By understanding their capabilities, professionals can push the boundaries of innovation in energy, manufacturing, and beyond.

Overview of High Melting Point Metals

In extreme environments where ordinary materials fail, a specialized group of elements dominates. Known as refractory metals, these substances maintain strength when exposed to conditions that vaporize lesser materials. Their unmatched durability stems from atomic bonds and structural configurations rarely found in nature.

Defining Refractory Metals and Their Unique Characteristics

Five elements form the core of this category: niobium, molybdenum, tantalum, tungsten, and rhenium. Each surpasses 2,000°C in heat tolerance—far exceeding conventional alternatives. A melting points data comparison reveals tungsten’s leadership at 3,422°C, with others following closely.

These materials share three critical traits:

- Body-centered cubic atomic structures (except rhenium)

- Electron configurations enabling ultra-strong bonds

- Natural resistance to deformation under stress

“Refractory metals redefine material limits—their thermal stability enables technologies once deemed impossible.”

Industrial Importance and Use Cases

Manufacturers rely on these elements for applications demanding relentless performance. Aerospace systems use tungsten alloys in rocket nozzles, while semiconductor plants employ molybdenum in high-energy reactors. The table below highlights key industrial pairings:

| Material | Key Property | Primary Application |

|---|---|---|

| Tantalum | Corrosion resistance | Chemical processing tanks |

| Rhenium | Creep resistance | Turbine blade coatings |

| Niobium | Superconductivity | MRI machine components |

Advanced fabrication methods like powder metallurgy overcome processing challenges. This technique preserves their innate qualities while enabling complex shapes for cutting-edge technologies.

List of Metals with Exceptional Melting Points

Modern engineering relies on materials that withstand conditions once considered unthinkable. Four elements form the frontline defense against thermal extremes, each offering distinct advantages across industries.

Tungsten: The Benchmark for Extreme Temperatures

Tungsten dominates thermal thresholds at 3,422°C – hotter than lava flows. This element maintains structural stability even when glowing white-hot, enabling its use in spacecraft shielding and radiation containment. Its electrical conductivity remains unaffected at 3,073K, explaining why 90% of incandescent bulbs contain tungsten filaments.

Rhenium, Tantalum, and Molybdenum in Focus

Rhenium follows closely with a 3,180°C threshold, prized for maintaining flexibility under stress. Jet engines use rhenium-coated blades to prevent warping during supersonic flights. Tantalum’s 2,966°C tolerance combines with acid resistance, making it essential for pacemakers and lab equipment.

| Material | Melting Temp | Signature Trait | Critical Use |

|---|---|---|---|

| Tungsten | 3,422°C | Thermal stability | Rocket components |

| Rhenium | 3,180°C | Stress resistance | Turbine systems |

| Tantalum | 2,966°C | Corrosion proof | Medical implants |

| Molybdenum | 2,620°C | Cost efficiency | Steel alloys |

Molybdenum proves most accessible commercially, reinforcing steel in skyscrapers and bridges. Its 2,620°C threshold balances performance with affordability – 40% cheaper than tungsten per kilogram. These materials collectively enable innovations from deep-space probes to life-saving surgical tools.

Understanding metal have highest melting point Fundamentals

At the atomic level, extraordinary properties emerge that define performance under thermal stress. The secret lies in electron behavior and structural organization unseen in common materials.

Atomic Structure and Metallic Bonding Explained

Refractory elements derive their resilience from partially filled d subshells. These outer-shell electrons form delocalized clouds, creating bonds three times stronger than typical metallic connections. A body-centered cubic arrangement locks atoms into rigid networks resistant to distortion.

This combination explains why breaking these bonds requires temperatures exceeding 2,500°C. As one researcher notes: “Their electron configuration acts like molecular armor—flexible enough to absorb energy but impervious to collapse.”

Linking Properties to Performance

Thermal endurance directly correlates with atomic stability. Materials with stronger electron sharing maintain hardness and resist oxidation even when glowing red-hot. The table below illustrates how structural factors influence real-world behavior:

| Element | d Electrons | Crystal Structure | Thermal Threshold | Oxidation Resistance |

|---|---|---|---|---|

| Tungsten | 5 | Body-centered | 3,422°C | Moderate |

| Rhenium | 5 | Hexagonal | 3,180°C | High |

| Tantalum | 3 | Body-centered | 2,966°C | Exceptional |

Groups 5-7 elements strike the ideal balance between electron availability and nuclear pull. This equilibrium enables applications where both heat and chemical resistance are non-negotiable—from fusion reactor linings to hypersonic vehicle skins.

Properties and Applications of Refractory Metals

Refractory metals deliver unmatched performance through a rare fusion of physical resilience and chemical stability. These materials thrive where others falter, enabling breakthroughs across critical industries.

Physical and Chemical Property Profiles

Three core attributes define these elements:

- Extreme hardness and density for structural reliability

- Thermal stability up to 3,400°C without deformation

- Resistance to acids, alkalis, and oxidation under stress

Their atomic structures create natural barriers against degradation. For example, tungsten maintains 95% hardness even at 1,600°C—critical for rocket nozzles enduring atmospheric re-entry.

Application in Aerospace, Electronics, and Manufacturing

From orbit to operating rooms, refractory metals solve complex challenges:

| Industry | Component | Material Advantage |

|---|---|---|

| Aerospace | Polаris missile nozzles | Tungsten’s heat deflection |

| Electronics | Capacitors | Tantalum’s corrosion resistance |

| Manufacturing | Steel alloys | Molybdenum’s cost-strength balance |

Niobium alloys powered Apollo lunar missions, while rhenium coatings prevent jet turbine warping. Even everyday tech relies on their properties—tungsten filaments light stadiums, and medical implants use tantalum’s biocompatibility.

Innovations in Refractory Metal Alloy Development

Cutting-edge manufacturing breakthroughs are redefining how industries approach extreme-temperature challenges. Engineers now craft specialized materials through advanced techniques that optimize performance beyond traditional limits.

Advances in Powder Metallurgy and Alloy Fabrication

Powder metallurgy dominates modern production for heat-resistant materials. This method compresses fine particles into precise shapes before sintering them at intense temperatures. The TZM alloy—containing 0.5% titanium and 0.08% zirconium—showcases this approach, achieving 40% greater creep resistance than pure molybdenum.

New sintering technologies maintain structural integrity while reaching 98% theoretical density. Controlled atmospheres prevent oxidation during processing, critical for maintaining the properties of tungsten-heavy alloys. These composites blend over 90% tungsten with nickel binders, balancing machinability with extreme heat tolerance.

Enhancing Creep Resistance and High-Temperature Strength

Strategic alloying transforms base materials into engineering marvels. Adding 22% rhenium to tungsten improves both strength and corrosion resistance at 1,600°C. Such combinations enable turbine components to operate reliably in aerospace systems where temperatures exceed 1,060°C.

Thorium-doped tungsten electrodes demonstrate how minor additives create major advantages. This modification enhances arc stability in welding tools while reducing energy consumption. Recent innovations in refractory metal technology focus on chromium-enhanced coatings that boost oxidation resistance without compromising ductility.

Manufacturers now tailor compositions for specific thermal and mechanical demands. These advancements ensure next-generation alloys meet evolving needs in energy production, space exploration, and advanced manufacturing sectors.

Challenges and Future Trends in High Temperature Materials

Engineers face complex hurdles when pushing materials beyond their thermal limits. While refractory elements excel under stress, manufacturing them into usable forms remains costly and technically demanding. Oxidation at extreme heat further complicates their deployment in critical systems like jet engines or power plants.

Overcoming Processing and Oxidation Limitations

Traditional production methods struggle with these materials’ brittleness. Creating thin sheets or intricate parts often requires energy-intensive processes. Protective coatings and alloy modifications now reduce degradation in corrosive gas environments, extending component lifespans in steel mills and chemical reactors.

Emerging Methods and Market Opportunities

Innovators are exploring additive manufacturing to bypass conventional limitations. 3D-printed components achieve precise geometries while maintaining heat resistance. The global market for these solutions is projected to grow 12% annually, driven by demands in aerospace and renewable energy sectors.

Future advancements will likely focus on expanding operational temperature ranges through nanotechnology. Researchers are developing composite materials that combine resistance to thermal shock with reduced weight—a critical need for next-gen spacecraft and fusion reactors.