Zinc is a chemical element with the symbol Zn and atomic number 30. It’s vital in many industries because of its density. This density makes zinc useful and efficient in making things.

We’ll explore zinc’s properties, focusing on its chemical makeup. We’ll see how these properties affect its use in various fields.

Introduction to Zinc and its Density

Zinc is the 24th most common element in the Earth’s crust. It plays a big role in many biological and industrial processes. The introduction to zinc covers its basic properties and its wide uses. Zinc is known for its excellent corrosion resistance, light weight, and ability to make strong alloys.

The significance of zinc density is clear when you know it’s about 7.14 g/cm³ at room temperature. This makes zinc better than metals like aluminum and iron for uses like galvanization and battery making. Knowing zinc’s density is key for engineers and manufacturers, as it helps choose the right materials.

What is Zinc and Its Key Properties?

Zinc, with the symbol Zn, is important in many fields and research. It’s a transition metal in group 12 of the periodic table. This makes it key to understanding metal behavior and properties.

Position in the Periodic Table

Zinc is the 30th element and has an atomic number of 30. It often has a +2 oxidation state, which is important for its chemical reactions. Zinc-64 is the most common stable isotope. These facts highlight zinc’s unique element properties, setting it apart from other metals.

Physical Appearance and Characteristics

Zinc has a bluish-white shine and is brittle at room temperature. It becomes soft and pliable when heated. Its density is about 7.133 grams/cm3 at 25 °C. This makes it valuable in industry.

Common Uses of Zinc

Zinc is used in many areas, like galvanizing to protect iron and steel. It’s also in batteries, alloys, and some supplements. Knowing how zinc is used helps us use its benefits well.

Electronic Configuration of Zinc

The electronic configuration of zinc is key to understanding its chemical properties. It has 30 electrons, arranged as [Ar] 3d10 4s2. This setup is important for zinc’s structure and its uses.

Understanding Atomic Structure

The electrons around the nucleus define zinc’s atomic structure. The full 3d subshell means the electrons are stable and less energetic. This makes zinc unique for uses like galvanization and battery production.

Impact on Reactivity and Corrosion Resistance

Zinc’s electronic configuration makes it less reactive. The completed d-subshell keeps the outer electrons from reacting easily. This boosts its corrosion resistance, making zinc vital in construction and manufacturing.

Metallic Bonding in Zinc

Zinc metal is special because of its metallic bonding. This bonding comes from zinc ions and a sea of free electrons. It’s key to zinc’s ductility and malleability, important for many uses.

Ductility and Malleability of Zinc

Zinc can be stretched into thin wires without breaking. This makes it useful in many manufacturing steps. It can also be shaped into sheets by hammering or rolling. These abilities make zinc versatile, used in construction, electronics, and cars.

Importance in Manufacturing Processes

Knowing about zinc’s metallic bonding helps use it better in making things. Its ductility is great for making alloys stronger and more resistant to rust. Zinc’s qualities are vital for making strong parts in modern engineering.

Physical Properties of Zinc

Zinc is a transition metal with many notable physical properties. These properties make it useful in different applications. Knowing its melting and boiling points is key for metal processing and manufacturing.

Melting and Boiling Points

The melting point of zinc is about 419.5°C. Its boiling point is around 907°C. These temperatures are relatively low, making zinc easy to process and use in metal casting.

These thermal thresholds make zinc a practical choice for manufacturing. It’s useful when heat is involved in the process.

Thermal and Electrical Conductivity

Zinc has a high heat capacity and conductivity. This makes it great for managing heat efficiently. It’s also a good electrical conductor, which is important for electronic devices.

The mobility of electrons in zinc ensures it performs well in various conditions. This is why it’s valuable in many applications.

When zinc is heated to about 100°C, it becomes more elastic and malleable. This shows how important temperature control is in manufacturing. Above 200°C, zinc turns into a grey powder.

This change highlights the connection between zinc’s melting and boiling points and its physical properties.

| Property | Value |

|---|---|

| Density | 7.13 g/cm³ |

| Color | Bluish-white |

| Melting Point | 420 °C |

| Boiling Point | 906 °C |

| Characteristics | Increased elasticity and malleability when heated |

| High Heat Capacity | Yes |

| Electric Conductivity | Good |

To learn more about zinc’s physical properties, check out this detailed resource. Understanding these properties helps professionals make better choices for using zinc in industry and commerce.

Density of Zinc – Key Facts

Studying zinc’s density gives us key insights into its properties and uses. Knowing zinc’s density in kg/m³ helps us compare it with other metals. This shows its special place among materials.

What is Zinc Density in kg/m³?

Zinc’s density is about 7,140 kg/m³. This makes zinc heavier than many other metals. It’s important for industries that use zinc in different ways.

Comparison with Other Metals

Comparing zinc’s density with other metals helps us understand its position. Here’s a table showing zinc’s density next to some other metals.

| Metal | Density (kg/m³) |

|---|---|

| Zinc | 7,140 |

| Aluminum | 2,700 |

| Copper | 8,960 |

| Lead | 11,343 |

This comparison shows zinc is heavier than aluminum but lighter than lead and copper. These differences are key for engineers and makers choosing materials.

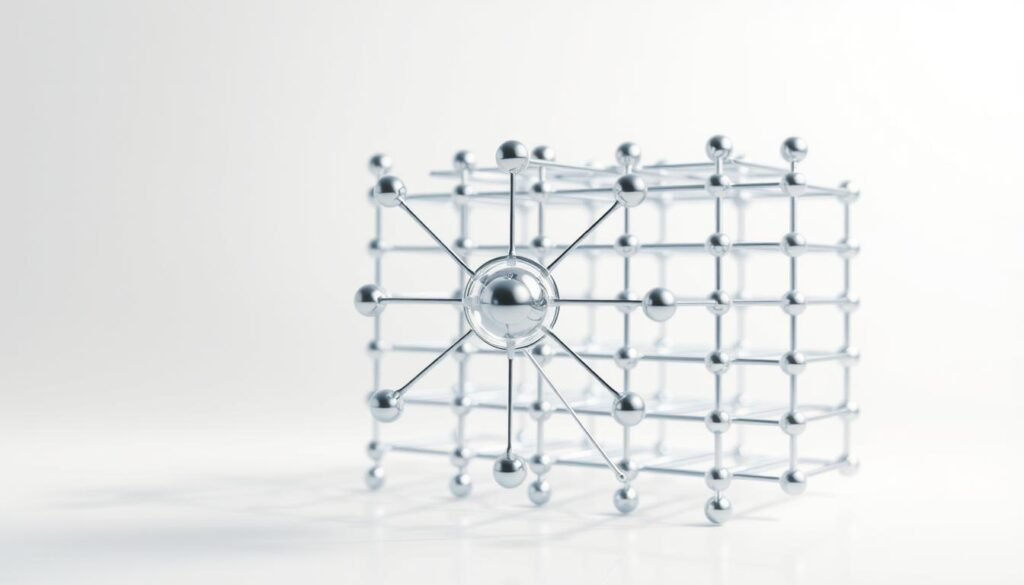

Atomic Packing Efficiency in HCP Lattice

Zinc has a unique hexagonal close-packed (HCP) structure. This structure is key to its physical properties. It allows for dense packing, making the most of the space in the material.

This packing pattern is important for understanding zinc’s density and other characteristics.

Understanding the Hexagonal Close-Packed Structure

The HCP structure of zinc has layers of atoms arranged in a specific way. Each atom is surrounded by twelve others, creating a highly efficient setup. This arrangement boosts atomic interactions, leading to better stability and density.

The efficient layering gives zinc a high packing efficiency of about 74%. This makes zinc one of the denser metals in its category.

Significance of Atomic Packing in Density

Atomic packing efficiency is key to a material’s density, including zinc’s. When atoms are packed closely, they reduce the metal’s volume, increasing its density. Zinc’s HCP structure shows how important geometric arrangements are in material science.

Understanding these concepts helps scientists and engineers tweak properties for different uses.

| Property | Value |

|---|---|

| Atomic Packing Efficiency | 74% |

| Coordination Number | 12 |

| Density of Zinc (g/cm³) | 7.14 |

| Crystal System | Hexagonal |

Exploring Zinc Alloy Density and Compounds

Zinc alloys are key in many industries because of their special properties. They mix zinc with other metals, changing their density. Knowing about alloys density helps us use these materials better in making things.

Common Zinc Alloys and Their Density

Many zinc alloys are used in different ways. Each one has a unique density because of its mix. Here’s a look at some common zinc alloys and their densities:

| Alloy Name | Composition | Density (g/cm³) |

|---|---|---|

| Brass | Copper and Zinc | 8.4 |

| Zamak | Zinc, Aluminum, Copper | 6.6 |

| Zinc Die Casting Alloy | Various Metals Including Al and Mg | 6.9 |

| Zinc Alloy 100 | Pure Zinc with Small Additives | 7.1 |

Impact of Alloying Elements

The elements added to zinc alloys change their density a lot. Metals like aluminum, copper, and magnesium affect strength, corrosion resistance, and weight. For example, adding copper makes brass, which is strong.

So, knowing how these elements change density is key. It helps us pick the right material for each job.

Factors Affecting Zinc Metal Density

The density of zinc is affected by several key factors. These factors are important for industries that use zinc. Temperature and pressure changes significantly impact how zinc behaves.

Temperature and Pressure Influence

Temperature directly affects zinc density. When temperature rises, zinc atoms move more, taking up more space. This makes the density go down. On the other hand, applying pressure compresses these atoms, slightly increasing density.

It’s vital to watch both temperature and pressure. They can change how zinc acts during processing and storage. Keeping an eye on these factors helps maintain quality in manufacturing.

The Role of Impurities

Impurities in zinc can change its density too. Different elements can mess with the way zinc atoms pack, causing density changes. These changes are important when looking at zinc alloys.

Impurities can affect not just density but also how well zinc works. Good quality control is needed to make sure zinc products have the right properties.

Measuring and Calculating Zinc Metal Density

Getting the right zinc density is key in many industries. There are several ways to do this, each with its own strengths. The choice depends on the zinc’s shape and how precise you need the measurement to be.

Density Measurement Techniques

- Archimedes Principle: This classic method calculates density by measuring the water displacement of the zinc sample. It is perfect for shapes that aren’t regular.

- Gas Pycnometry: For very precise measurements, gas pycnometry is the go-to. It finds the zinc’s density by measuring the gas it displaces.

- X-ray Diffraction: This advanced technique gives deep insights into zinc’s atomic structure. It helps scientists figure out its density through complex calculations.

Comparison of Measurement Methods

| Method | Precision | Sample Type | Application |

|---|---|---|---|

| Archimedes Principle | Moderate | All shapes | General density measurement |

| Gas Pycnometry | High | Homogeneous solids | Research and quality control |

| X-ray Diffraction | Very High | Crystalline solids | Advanced material characterization |

Application of Zinc Metal Density

Zinc density is key in manufacturing. It affects how well products work, last, and perform. Zinc is vital in making things like die cast parts and galvanized items.

Role in Industrial Manufacturing

Zinc density is important for parts to be strong and work well. This is true in the car and machine industries. Zinc parts need to handle tough conditions.

By controlling zinc’s density, makers can improve its strength. This leads to better products that are safer and more efficient.

Use in Counterweights and Ballast

Zinc is great for counterweights and ballast because of its density. It helps things work smoothly and safely. Builders and transporters use zinc for balance and support.

Its use shows zinc’s reliability and effectiveness. It’s a key part of many industries.

Conclusion

Zinc’s properties, like its density, are key in many industries. Its density and physical traits help it in manufacturing and marine uses. It’s important to consider temperature, pressure, and impurities for the best results.

This summary shows zinc’s big role in industry and science. As things change, zinc’s special traits will keep helping us make things better and more sustainable. Learning about zinc’s density is essential for those interested in metals and their uses.