Knowing how heat affects industrial alloys is vital for safe and efficient manufacturing. When materials reach their phase-change thresholds, their behavior shifts dramatically. This principle is especially critical for components exposed to extreme conditions, from aerospace systems to chemical processing equipment.

Specialized alloys don’t liquefy at a single fixed value. Instead, they transition between states across a range influenced by their chemical makeup. For example, common industrial blends soften between 1,370°C and 1,530°C (2,500°F–2,800°F). This variation stems from differing ratios of chromium, nickel, and other stabilizing elements.

Engineers rely on precise melting point data to prevent structural failures during welding or casting operations. Choosing the right grade ensures components withstand operational stresses without deforming. Overlooking these thresholds risks costly production errors or equipment malfunctions.

Modern fabrication techniques demand thorough material science knowledge. From turbine blade forging to pipeline construction, temperature management separates successful projects from hazardous outcomes. This guide explores how to leverage these thermal properties effectively across industries.

Introduction to Stainless Steel and Its Melting Behavior

Modern manufacturing relies on materials that maintain strength under extreme conditions. One widely used alloy combines durability with adaptability, forming the backbone of countless industrial and consumer products.

Overview of Alloy Composition

At its core, this material blends iron with chromium and nickel. Chromium forms a protective oxide layer, while nickel enhances flexibility. These elements create a balance between structural integrity and corrosion resistance.

Pure metals like iron or chromium have fixed thermal thresholds. When combined, their interactions create a melting range rather than a single temperature. This behavior demands careful analysis during production processes.

Why Thermal Management Matters

Precision matters when shaping components through welding or casting. Exceeding specific heat levels alters molecular bonds, weakening joints or causing deformations. Even brief temperature spikes can compromise quality.

Industrial applications require strict protocols. For example, aerospace parts undergo rigorous testing to ensure they withstand operational stresses. Proper thermal control prevents costly rework and ensures safety standards.

Understanding these principles separates functional designs from potential failures. Manufacturers prioritize material science insights to optimize both performance and longevity.

Fundamentals of Melting Points in Metals

Every material has a thermal threshold where its physical properties transform irreversibly. For engineers, this knowledge shapes decisions in everything from furnace design to safety protocols.

Definition and Scientific Principles of Melting

A substance reaches its melting point when atomic bonds loosen enough to shift from rigid structures to free-flowing particles. Heat energy disrupts the crystalline lattice, allowing molecules to slide past one another. This transition occurs at precise temperatures under standard pressure.

Comparison with Other Materials

Metals generally require far higher heat than everyday substances to reach their liquid state. For example:

- Aluminum softens at 660°C (1,220°F)

- Copper transitions near 1,085°C (1,985°F)

- Iron-based alloys withstand up to 1,500°C+ (2,732°F)

These differences explain why melting points of metals dictate their industrial roles. Materials with higher thresholds handle extreme environments like jet engines or molten salt reactors. Lower-melting metals excel in electrical wiring or casting molds.

Thermal behavior also impacts recycling processes. Separating mixed scrap relies on understanding each component’s phase-change characteristics. Precise temperature control ensures efficient material recovery without degradation.

Factors Affecting the Stainless Steel Melting Point

Material engineers face complex challenges when determining thermal thresholds for industrial alloys. Multiple variables influence how these materials respond to heat, requiring careful analysis during production planning.

Alloy Composition and Melting Point Depression

Every element added to iron alters its thermal behavior. Pure iron melts at 1,535°C, but adding chromium (1,890°C) and nickel (1,453°C) creates competing effects. Chromium increases corrosion resistance but may elevate thresholds, while nickel lowers them for improved workability.

This phenomenon, called melting point depression, explains why blended materials transition across ranges rather than fixed values. Carbon and trace elements further modify these interactions, creating distinct profiles for different grades.

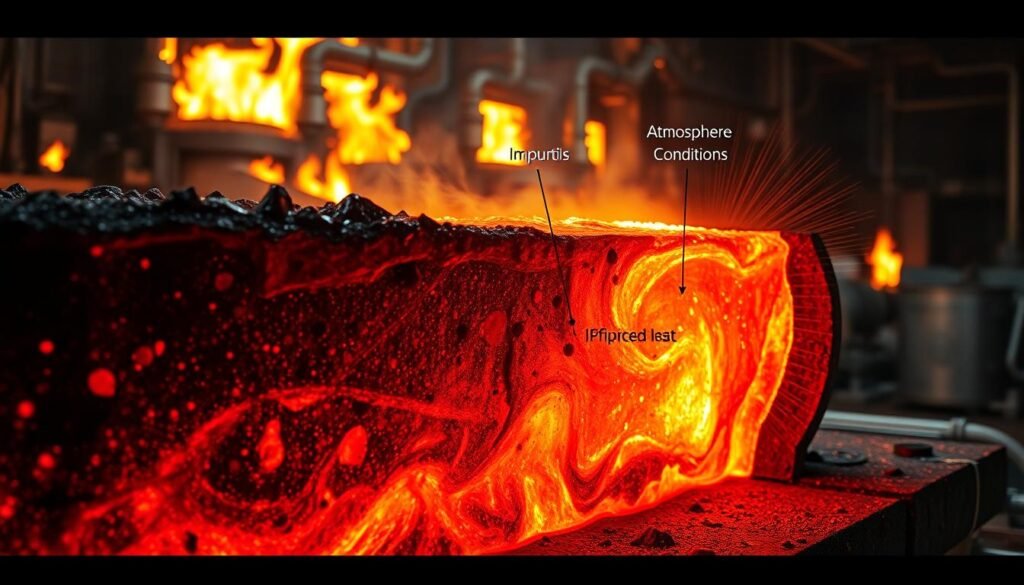

Role of External Conditions and Heat Exposure

Environmental factors significantly impact phase transitions. Increased atmospheric pressure can raise thresholds by 50–100°C in industrial furnaces. Conversely, oxygen-rich environments accelerate oxidation, potentially weakening structures before liquefaction occurs.

Heating rates also matter. Rapid temperature spikes might bypass critical stress points, while gradual increases allow controlled molecular adjustments. Engineers balance these variables to maintain structural integrity during casting or welding operations.

Understanding the stainless steel melting point: Temperature Ranges and Grade Variations

Material selection becomes critical when components face extreme thermal loads. Different formulations exhibit distinct phase-change behaviors, directly impacting manufacturing methods and performance outcomes.

Thermal Thresholds by Formulation

The grade 304 stainless steel dominates industrial applications with its 1,400–1,450°C range. This austenitic variety balances workability and heat tolerance for food processing equipment and architectural elements. Comparatively, grade 316 stainless steel operates in narrower bands (1,375–1,400°C) while excelling in marine environments due to enhanced molybdenum content.

| Grade | Temperature Range | Key Characteristics |

|---|---|---|

| 304 | 1,400–1,450°C | General-purpose corrosion resistance |

| 316 | 1,375–1,400°C | Superior chemical stability |

| 321 | 1,400–1,425°C | Titanium-stabilized for welding |

| 430 | 1,425–1,510°C | High chromium for oxidation resistance |

Elemental Impact on Thermal Stability

Nickel content plays a decisive role in lowering transition thresholds. Austenitic grades contain 8–12% nickel, explaining their reduced liquefaction temperatures versus ferritic counterparts. Chromium concentrations above 16% primarily boost oxidation resistance rather than significantly raising melting limits.

Molybdenum additions in grade 316 stainless steel slightly compress its operational range compared to grade 304 stainless steel. These compositional tweaks allow engineers to fine-trade thermal resilience against other performance factors like machinability or stress corrosion cracking resistance.

Practical Applications and Industry Relevance

From jet engines to kitchenware, thermal thresholds dictate real-world performance. Engineers balance material capabilities with operational demands, ensuring components withstand stress without compromising safety. This intersection of science and practicality shapes industries where failure isn’t an option.

Implications for High-Temperature Fabrication

Manufacturing processes demand precise heat control. Welding and forging operations require temperatures approaching 1,000°C – close enough to alter strength properties but below liquefaction thresholds. A steel basket designed for 800°C can typically hold double the load compared to versions used at 1,000°C due to retained tensile capacity.

| Temperature | Tensile Strength | Application Example |

|---|---|---|

| 800°C | 450 MPa | Industrial furnace racks |

| 1,000°C | 220 MPa | Exhaust system components |

| 1,200°C | 90 MPa | Aerospace heat shields |

Design Considerations Across Sectors

Chemical plants use alloys with enhanced corrosion resistance for reactor vessels, while kitchen equipment prioritizes food-safe surfaces. Automotive engineers select materials that maintain structural integrity near engine blocks, where temperatures exceed 700°C during operation.

These applications demonstrate why thermal data drives material selection. From skyscraper frameworks to commercial ovens, understanding phase-change boundaries prevents catastrophic failures and extends product lifespans.

Determining and Measuring Melting Points

Accurate thermal analysis forms the backbone of material reliability in extreme environments. Laboratories deploy advanced techniques to verify phase transitions, ensuring components meet rigorous performance standards. These methods prevent defects in heat treatment processes and maintain structural integrity across industries.

Capillary Methods and Differential Scanning Calorimetry (DSC)

The capillary technique remains a cornerstone for determining melting points. Technicians seal powdered samples in glass tubes, heating them at 1°C per minute. Visual confirmation of liquefaction provides clear transition evidence. This approach suits quality checks for precise thermal properties in production batches.

DSC offers superior precision by tracking energy absorption during phase changes. Sensors detect heat flow deviations as samples melt, generating exact temperature profiles. Engineers rely on these graphs to identify impurities or alloy inconsistencies affecting performance.

Optical and Temperature Sensor Techniques

Infrared pyrometers measure surface radiation without contact, ideal for reactive metals. High-speed cameras capture structural shifts in real time, revealing subtle melting indicators. These non-invasive methods reduce contamination risks during testing.

Thermocouples embedded in furnaces provide continuous temperature feedback. Combined with optical data, they create comprehensive thermal maps. Modern labs often cross-validate results using multiple instruments, ensuring measurement repeatability across diverse material grades.

Conclusion

Industrial success hinges on precise thermal thresholds in alloy selection. The phase-change range of 1,370–1,530°C in chromium-rich alloys directly impacts their performance under stress. Variations in nickel and iron content create distinct thermal profiles, guiding engineers toward optimal material choices.

Chromium boosts oxidation resistance but requires careful balancing with other elements. Nickel enhances flexibility while slightly lowering transition temperatures. These compositional nuances determine suitability for critical applications, from skyscraper frameworks to jet engine components.

Selecting the right grade prevents structural compromises during fabrication. Aerospace systems demand tighter thermal tolerances than architectural projects, while chemical plants prioritize corrosion resistance. Proper alloy matching ensures safety and efficiency across industries.

Understanding these relationships transforms raw metals into reliable solutions. By considering both composition and operational demands, manufacturers unlock superior durability in extreme environments.