In the world of materials, knowing about polyurethane density is key. It’s important for many industries that use this versatile compound. The different types of polyurethane affect its durability and strength.

How dense a foam is can change how well it works. This is true for many uses of polyurethane. By looking at the different densities, industries can pick the best material for their needs.

For more details, check out this article on low-density and high-density polyurethane.

Introduction to Polyurethane Density

Understanding polyurethane density is key in many industries. It’s used in making furniture and car parts. Polyurethane density is how much it weighs per unit volume. This shows how tight the material is, affecting its performance.

The importance of foam density is huge. It affects strength, flexibility, and how well it keeps heat out. Polyurethane can be made to fit different needs by changing its density. This makes it useful for many uses.

Knowing how to classify polyurethane by density helps pick the right one for a project. It also helps us understand how it works under different conditions. This section sets the stage for deeper looks into foam’s characteristics and uses.

What is Foam Density?

Foam density is the weight per volume of foam, usually in pounds per cubic foot. This foam density definition is key to knowing how well different foams work. For example, a two-pound foam means there are two pounds in every cubic foot.

The tightness of foam affects its strength and support. More dense foam is more compact, making it better at staying firm over time. When you need foam to last, picking the right density is important.

Knowing about foam density helps in making better choices for projects. This is true in furniture making and even for shipping materials. For more on foam types and their densities, check this out.

Importance of Polyurethane Density in Applications

The importance of polyurethane density is huge, in many industrial uses. Polyurethane foams, with their density, play many roles. They are used for insulation in buildings and for softening car seats. The denser foams are stronger and last longer, perfect for heavy-duty tasks.

On the other hand, lighter foams are flexible and cheaper. They’re great for foam applications like air filters and soft cushions. These foams are a smart choice for saving money without losing quality.

The application significance of polyurethane density varies by industry. Aerospace needs strong, light foams to save weight and keep things sturdy. Furniture makers prefer softer foams for comfort and cost savings. Knowing the right foam density is key for success in many fields.

| Densities | High-Density Foam | Low-Density Foam |

|---|---|---|

| Durability | Excellent, withstands heavy loads | Moderate, best for lighter applications |

| Cost | Higher cost due to material strength | More economical and accessible |

| Flexibility | Less flexible, more rigid | Highly flexible, adaptative to needs |

| Common Uses | Automotive seats, aerospace insulation | Filtration systems, cushioning |

Factors Influencing Polyurethane Density

Understanding what affects polyurethane density is key for manufacturers. They aim to make foam that works best. These factors are important during production and shape the final product’s features.

Blowing Agents

Blowing agents are essential in making polyurethane foam. They create gas bubbles that make the foam expand. This expansion changes the foam’s density.

The type of blowing agent used affects the foam’s structure. This, in turn, impacts the foam’s density and how well it performs.

Chemical Additives

Chemical additives, like stabilizers and fillers, change polyurethane foam’s properties. They can greatly affect the foam’s density. The additives’ type and amount are critical for achieving the right foam characteristics.

These additives help ensure the foam meets specific needs. This is important for different uses of the foam.

Understanding Foam Cell Structures

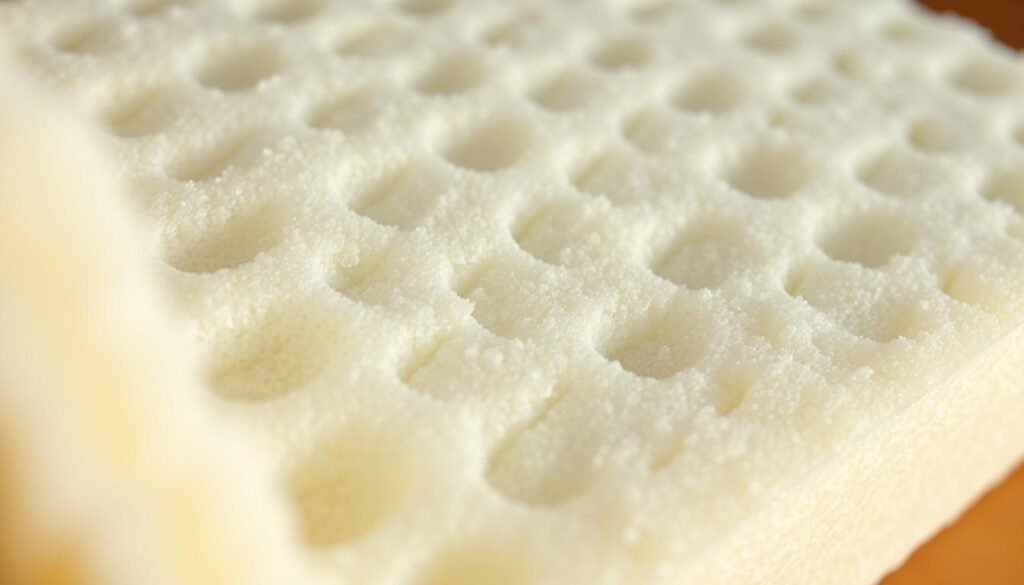

The foam cell structure is key to understanding polyurethane foams. There are two main types: open cell and closed cell. Each type has its own set of properties, depending on cell size and density.

High-density foams have small, tightly packed cells. This makes them great for keeping things warm or cool. On the other hand, low-density foams have big, open cells. These allow air and moisture to pass through, making them good for filtering and cushioning.

Cell size is important for foam performance. Smaller cells make the foam denser, which means it’s better at supporting weight and resisting compression. Larger cells, found in low-density foams, make the foam lighter and more flexible. But, they don’t offer as much strength or insulation.

Choosing between open cell and closed cell foams depends on what you need. Closed cells block moisture and air, making them great for insulation. Open cell foams, while not as good at keeping things warm or cool, are perfect for letting air through. This is why they’re used in things like bedding and sound panels.

| Foam Type | Cell Structure | Density | Applications |

|---|---|---|---|

| High-Density Foam | Small, compact cells | High density | Insulation, furniture |

| Low-Density Foam | Large, open cells | Low density | Filtration, soundproofing |

| Open Cell Foam | Interconnected cells | Variable density | Mattresses, acoustics |

| Closed Cell Foam | Sealed cells | Variable to high density | Marine applications, insulation |

Polyurethane Density: High vs Low

High-density and low-density polyurethane foams have big differences. These differences affect how they are used in different fields. Knowing what makes each type special helps us choose the right one for our needs.

Characteristics of High-Density Polyurethane Foam

High-density foam weighs between 10 to 20 lbs/ft³. It’s very strong and can handle a lot of pressure. This makes it great for places where things need to stay in shape well.

It doesn’t get squished down much, even when pressed hard. This is why it’s perfect for tough jobs. High-density foam stays strong and works well for a long time.

Advantages of Low-Density Polyurethane Foam

Low-density foam weighs less, from 1 to 6 lbs/ft³. It’s cheaper and bends easily. This makes it good for things like packing and keeping homes warm.

It also doesn’t weigh much and helps block out sounds. This makes it useful for many things. For example, it’s great for softening falls and keeping things warm. Learn more about how it compares to high-density foam.

Applications of High-Density Polyurethane Foam

High-density polyurethane foam is key in many fields, where it’s needed for its strength and performance. It’s widely used in areas that need tough materials to last long.

In heavy-duty gasketing, this foam shines. It creates a tight seal, stopping leaks and keeping systems working right. It also helps in reducing noise and vibrations, making things quieter and lasting longer.

For sound control, polyurethane foam is a big help, mainly in big buildings. Products like Poron® and Isoloss™ by 3M™ show how well this foam works. They’re used in cars, planes, and buildings, where they need to handle shocks and keep things quiet.

Also, it’s vital in making car parts and insulating planes. Its ability to keep things warm or cool and quiet makes vehicles and aircraft better.

Applications of Low-Density Polyurethane Foam

Low-density polyurethane foam is used in many industries because it’s versatile and affordable. It’s great for making lightweight packaging that protects items well. It also keeps things warm or cool, which is why it’s used in appliances and buildings.

In cars, this foam makes seats more comfortable. It’s also durable, which is good for places that get a lot of use. It’s also used in door gaskets and seals because it’s flexible and seals well.

It’s also used in filters because it catches particles but lets air pass through. This is important for keeping air and water clean. Using low-density foam helps save money without sacrificing quality, making projects more efficient and cost-effective.

| Application Area | Benefits | Typical Uses |

|---|---|---|

| Packaging | Cushioning and protection | Shipping materials, electronics packaging |

| Construction | Thermal insulation | Insulating panels, roofing |

| Automotive | Comfort and durability | Seat cushions, headliners |

| Filtration | Effective particle capture | Air filters, water filters |

Custom Fabrication and Polyurethane Density

Custom polyurethane fabrication is key in many industries. It lets makers create materials just right for certain needs. This means products can work better in unique situations.

Things like car parts and everyday items benefit from this. They get made to fit specific needs, making them perform well.

Custom die-cut foam parts bring precision and dependability. They can be made into complex shapes, improving product quality. For example, foam gaskets made this way seal better, helping products work better overall.

Getting the foam density just right is important. It makes sure materials fit the project perfectly. This boosts efficiency and makes components last longer. It’s why custom polyurethane fabrication is vital for businesses wanting to stay ahead.

By focusing on custom needs, industries can solve their specific problems. This drives innovation and helps them grow.

Conclusion

Understanding polyurethane density is key to knowing how well products work. It shows how different densities affect what products are best for certain uses. Polyurethane foam is used in many fields, from cars to buildings.

High-density and low-density polyurethane foams have their own benefits. They meet different needs. This material is very adaptable and plays a big role in new ideas in industries.

Knowing about polyurethane density helps make better choices. It’s important for both makers and users. This knowledge lets us use polyurethane to its best.

Exploring polyurethane density shows its big role in science and product making. It helps us make better products and use resources wisely. This knowledge is key for the future.