ABS (Acrylonitrile Butadiene Styrene) is a well-known thermoplastic polymer. It’s known for its strong and durable nature. Knowing about ABS plastic density is key for picking the right materials in many fields.

This includes the car industry, electronics, and medical devices. This guide covers the main points about ABS properties. It shows how density affects product design and how well they work.

It talks about how to measure density, what affects it, and the environment. This detailed look aims to give you important info on ABS plastic density in making and using products.

Understanding ABS Plastic

ABS plastic is a common thermoplastic made from acrylonitrile, butadiene, and styrene. This mix gives it special properties. Acrylonitrile makes it resistant to chemicals, butadiene boosts its impact strength, and styrene adds rigidity.

ABS is both light and durable, making it easy to work with. It’s used in cars, electronics, and home goods. Its strong impact resistance means it works well in many situations.

ABS is a top pick in many fields because of its unique properties. For more details on ABS, check out this link.

The Importance of Density in ABS Plastic

Knowing about ABS plastic density is key to seeing how well it works in different uses. ABS usually has a density between 1.03 and 1.06 g/cm³. This range affects how strong and stiff the plastic is.

ABS with higher density is better for parts that need to be strong and stiff. But, ABS with lower density is easier to work with. This makes production faster and cheaper.

Density is more than just about weight. It also helps in making designs that are both light and strong. This is important for meeting engineering needs. For more details, check out this resource.

In summary, knowing about ABS plastic density is vital for picking the right material and designing products. By understanding how density impacts strength and design, makers can improve their products’ quality.

ABS Plastic Density Overview

The density of ABS plastic is key in many industries. It usually ranges from 1.03 to 1.06 g/cm³. This range affects its physical characteristics, making it durable and effective in various products.

Knowing the material properties of ABS is vital. Different densities come from changes in composition and how it’s made. These changes affect ABS’s strength and how it’s used, making sure it fits each need.

Engineers and designers can use this info to choose the right ABS for their projects. By understanding the density and its impact, they can improve performance and consistency.

Factors Influencing ABS Plastic Density

The density of ABS plastic is influenced by several key factors. These factors include the composition of the plastic and how it’s made. Knowing these can help us understand why ABS products can vary in density.

Composition of ABS

ABS is made of acrylonitrile, butadiene, and styrene. The amount of styrene affects the plastic’s density. Styrene makes the plastic denser because of its molecular structure.

Additives and fillers can change the ABS formula. This allows for different densities for various uses. Knowing this helps choose the right ABS for different needs.

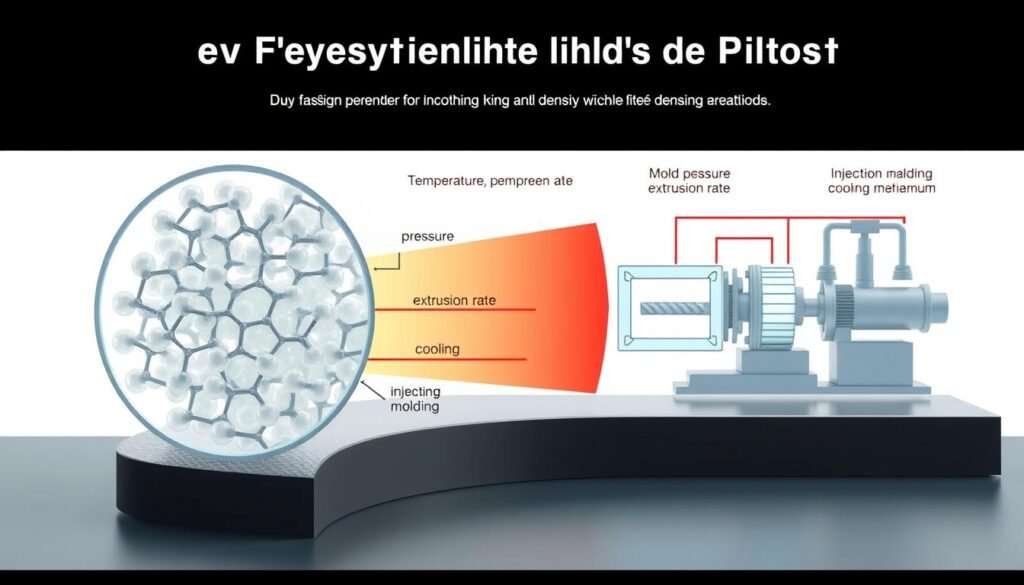

Manufacturing Methods

How ABS is made also affects its density. Techniques like injection molding and extrusion play a role. Temperature, pressure, and cooling rates during production can change the plastic’s molecular structure.

These changes can lead to slight density variations. Understanding these factors is key to improving production and getting the desired material properties.

Measurement Techniques for ABS Plastic Density

Getting the right density of ABS plastic is key for quality and performance. The Archimedes Principle and ASTM D792 standards are top choices. They offer solid ways to measure density accurately.

Archimedes Principle

The Archimedes Principle is a trusted method. It involves dipping ABS plastic in a fluid. This way, it finds density by seeing how much fluid is pushed aside.

This method is simple and reliable. It shows density through something we can see. This makes it popular in many places.

ASTM D792 Standards

ASTM D792 standards give clear steps for plastic density, like ABS. They help labs get the same results. They use water displacement and liquid pycnometers.

Using ASTM D792 makes sure density is right. This is important for keeping ABS plastic quality high.

Impact of ABS Plastic Density on Performance

The density of ABS plastic greatly affects its performance in different industries. Its density impacts the material’s mechanical properties.

ABS with higher density has better tensile strength and impact resistance. This makes it great for heavy-duty uses. It’s perfect for the automotive and construction sectors, where durability is key.

On the other hand, lower density ABS makes manufacturing easier. It uses less energy and cuts down cycle times. This boosts productivity and saves costs, appealing to manufacturers looking to improve their processes.

Mechanical Properties of ABS Plastic

ABS plastic is known for its versatility. It has strong tensile strength and high impact resistance. These qualities make it useful in many fields.

Tensile Strength

ABS plastic has a tensile strength of 40 to 50 MPa. This makes it great for carrying loads and withstanding stress. It keeps products strong and stable.

Impact Resistance

ABS also stands out for its impact resistance. It scores 200 to 600 J/m in Izod impact tests. This shows it can handle tough impacts well. It’s perfect for places where things need to last.

Applications of ABS Plastic Across Industries

ABS plastic is very versatile and is key in many fields. It’s used in cars, electronics, and medical tools. Its strength, beauty, and safety make it a top choice.

Automotive Industry

In cars, ABS is used for dashboards and door panels. It’s strong and light, which helps cars use less fuel. Its look matches what car makers want, making it popular.

Consumer Electronics

ABS makes phone cases and appliance covers last longer. It’s good at keeping electricity out, making devices safer and lasting longer. This is what makers look for in their products.

Medical Equipment

ABS is safe for medical tools because it works well with cleaning. It’s used for parts that need to be very safe. This ensures doctors and patients can rely on it.

Advantages and Disadvantages of ABS Plastic Density

ABS plastic has many benefits due to its density and physical properties. It has high impact resistance and is lightweight. This makes it great for many uses. It’s also easy to work with and can be designed well, boosting productivity in different fields.

But, ABS plastic also has some downsides. Its low melting point, around 105°C, limits its use in hot places. This can cause it to bend or warp, making it hard to choose for some jobs. Also, ABS can be damaged by certain chemicals, which might affect how well products work. For more details, check out the ABS plastic properties page.

Environmental Considerations of ABS Plastic

ABS plastic has both good and bad sides when it comes to the environment. It can be recycled many times without losing its quality. This helps in creating a circular economy, where materials are used over and over again.

But, making ABS plastic does harm the environment. The process uses petrochemicals, which release greenhouse gases. To fix this, companies are working on making ABS plastic more eco-friendly. They’re looking into using bio-based materials and making manufacturing systems more closed-loop.

| Aspect | Details |

|---|---|

| Recyclability | Recyclable with minimal property loss, supports circular economy |

| Environmental Impact | Petrochemical production can increase greenhouse gas emissions |

| Sustainability Initiatives | Use of bio-based materials and closed-loop manufacturing systems |

Conclusion

Understanding ABS plastic density is key for professionals in many fields. It helps in choosing the right materials and designing products. ABS plastic’s density, due to its special mix and how it’s made, affects its strength. This makes it great for many uses.

ABS plastic is strong and can handle impacts well. But, we must think about its impact on the environment. Finding a balance between using its benefits and being green is important today. This helps in making products better and using resources wisely.

This guide is meant to help experts understand ABS plastic density. It aims to guide them in making choices that meet both performance and environmental needs.