Known for its atomic number 22 and symbol Ti, this element boasts exceptional heat resistance compared to common structural metals. While exact measurements vary slightly between sources, its thermal threshold typically ranges between 1,668°C and 1,725°C. This places it significantly higher than aluminum alloys and even surpasses many steel grades.

Engineers value these thermal properties when designing components for extreme environments. Jet engines, spacecraft parts, and surgical tools all benefit from the material’s ability to maintain integrity under intense heat. Medical devices requiring repeated sterilization demonstrate how this characteristic impacts daily life.

The temperature tolerance directly influences manufacturing techniques and cost-efficiency. Advanced welding methods and specialized casting processes become necessary when working with such heat-resistant substances. These factors contribute to both the material’s premium status and its specialized applications.

Understanding these thermal limits helps professionals select optimal materials for critical projects. From deep-sea drilling equipment to high-performance automotive systems, precise knowledge of thermal thresholds ensures safety and durability. This guide will explore practical implications through comparative analysis and real-world examples.

Introduction to Titanium and Its Unique Properties

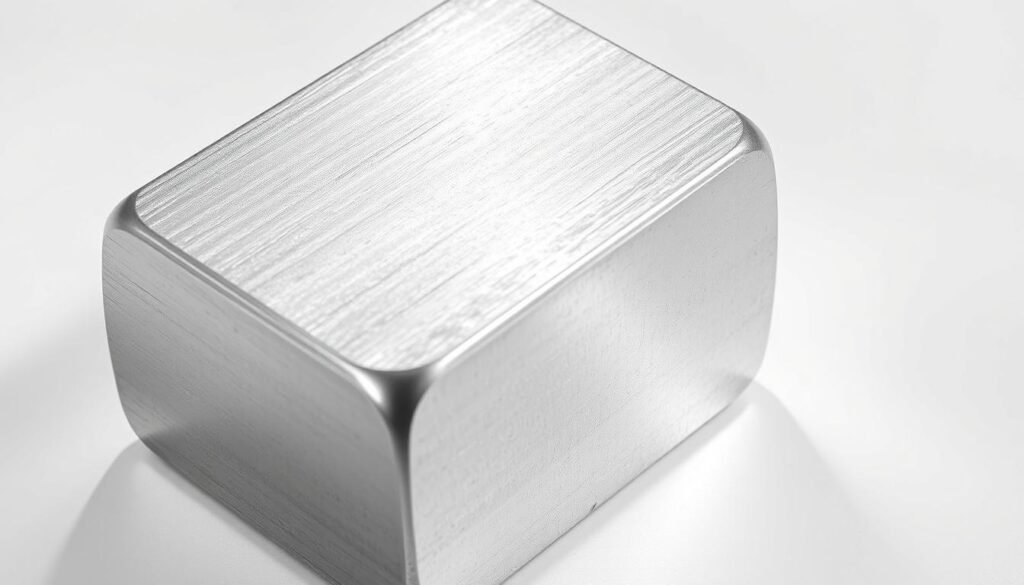

Standing out among industrial metals, this silver-gray element combines rare qualities that redefine material performance. With a density 60% higher than aluminum yet double the strength of common alloys, it delivers unmatched efficiency for weight-sensitive designs.

Overview of Titanium as a Versatile Metal

Industrial leaders value this material’s 4.5 g/cm³ density paired with tensile strengths reaching 1,400 MPa in advanced alloys. Unlike steel, it resists saltwater corrosion better than platinum, making it ideal for marine hardware and offshore rigs.

Medical breakthroughs showcase another advantage: biological compatibility. Hip replacements and dental implants bond with human tissue without rejection risks. This dual capability in engineering and healthcare underscores its adaptability.

Importance of High Melting Point in Modern Applications

Thermal stability proves crucial in extreme environments. Jet turbine blades withstand prolonged heat exposure that would warp conventional metals. Chemical reactors maintain structural integrity during high-temperature processes thanks to this characteristic.

Energy sectors benefit through durable geothermal piping systems. Reduced maintenance needs and extended equipment lifespans directly result from these thermal advantages. Such resilience drives innovation across multiple technical fields.

History and Discovery of Titanium

In 1791, British clergyman William Gregor stumbled upon an unidentified substance while studying magnetic sand from Cornwall’s Manaccan Valley. His meticulous analysis revealed iron oxide mixed with a mysterious white compound – later recognized as titanium dioxide.

Early Discoveries and Naming Origins

German chemist Martin Klaproth independently isolated the same oxide four years later. He christened the element after Greek mythology’s Titans, declaring: “The extraordinary strength of these mythological beings perfectly represents this remarkable metal.”

For over a century, scientists struggled to isolate pure samples. Conventional smelting techniques failed spectacularly – carbon reduction attempts created brittle titanium carbide instead of usable metal.

Evolution of Extraction and Refining Techniques

Breakthroughs came in 1910 when Matthew Hunter developed a sodium reduction method. While revolutionary, his processes remained impractical for large-scale use until William Kroll’s 1940s magnesium-based approach.

Modern production builds on these foundations. Advanced chloride chemistry and vacuum distillation now yield ultra-pure material. This progression transformed titanium from laboratory curiosity to aerospace essential.

“Kroll’s magnesium reduction method didn’t just extract metal – it unlocked industrial possibilities we’re still exploring today.”

Titanium Melting Point: Key Facts and Figures

When comparing structural metals, thermal thresholds separate ordinary materials from engineering superstars. Pure titanium transitions from solid to liquid between 1,668°C (3,034°F) and 1,725°C (3,135°F), outperforming steel by 220°C and aluminum by over 1,100°C. This range reflects measurement variations caused by purity levels and testing conditions.

| Metal | Melting Point (°C) | Boiling Point (°C) |

|---|---|---|

| Titanium | 1,668-1,725 | 3,287 |

| Steel | 1,370-1,538 | 2,750 |

| Aluminum | 660 | 2,470 |

Manufacturers face unique challenges working with this element’s thermal thresholds. Specialized furnaces reaching 1,800°C become essential for casting components. Welding requires inert atmospheres to prevent contamination at extreme temperatures.

Why do technical manuals list different values? Impurity concentrations as low as 0.5% can shift phase-change temperatures. Vacuum measurement environments typically yield higher precision than standard lab setups.

“Designing jet engine components demands millimeter-perfect thermal data – guesswork melts budgets faster than metals.”

From geothermal pipelines to rocket nozzles, exact temperature specifications determine project success. Engineers combine this data with conductivity rates (21.9 W/m·K) and heat capacity (0.523 J/g·K) to model material behavior under stress.

Atomic and Chemical Properties of Titanium

At the subatomic level, this element reveals why it outperforms common metals in extreme conditions. With 22 protons and an electron arrangement of [Ar] 3d² 4s², its atomic framework creates unique interactions under heat stress. This configuration allows electrons to form robust connections between neighboring atoms.

Atomic Structure and Electron Configuration

The metal’s hexagonal crystal arrangement at room temperature packs atoms tightly, like eggs in a carton. Each atom shares electrons across six neighbors, creating a stable lattice. When temperatures reach 882°C (1,620°F), the structure shifts to a more open cubic pattern.

| Property | Room Temperature | High Temperature |

|---|---|---|

| Crystal Structure | Hexagonal (hcp) | Cubic (bcc) |

| Lattice Constant (a) | 295.05 pm | 332 pm |

| Phase Transition | N/A | 882°C |

Metallic Bonding and Lattice Arrangements

Partially filled d-orbitals enable electrons to move freely, acting like glue between atomic nuclei. This bonding style requires immense energy to disrupt – explaining why industrial furnaces struggle to liquefy the material. The hexagonal structure’s density drops by 4% during phase changes, affecting how engineers shape components.

Paramagnetic behavior arises from unpaired electrons reacting to magnetic fields. This trait helps sort scrap metal while recycling. Unlike iron or nickel, the element won’t stick to magnets but aligns weakly with strong fields.

“Titanium’s dual crystal structures act like molecular armor – rigid at room temperature, flexible when heated.”

Factors Influencing the Titanium Melting Point

Material composition determines performance limits in extreme heat environments. Two primary factors govern thermal stability: elemental purity and intentional alloy mixtures. Even minor deviations dramatically affect phase transitions during industrial processes.

Impact of Purity and Impurities

Oxygen concentrations as low as 0.2% reduce thermal resistance by 35°C in commercial-grade material. Nitrogen and carbon impurities create similar effects by disrupting atomic bonds. Manufacturers combat this through vacuum arc remelting, achieving 99.9% purity for aerospace components.

| Alloy | Composition | Thermal Threshold |

|---|---|---|

| CP Grade 2 | 99% Ti | 1,668°C |

| Ti-6Al-4V | 6% Al, 4% V | 1,655°C |

| Ti-5Al-2.5Sn | 5% Al, 2.5% Sn | 1,645°C |

Alloying Elements and Phase Transformations

Aluminum additions lower density while maintaining structural integrity up to 540°C. Vanadium enhances beta-phase stability, enabling complex shaping during hot forming. These modifications explain why Ti-6Al-4V dominates 50% of aerospace applications despite its reduced thermal threshold.

“Controlling alloy chemistry isn’t just science – it’s the difference between turbine blades that last years versus months.”

Phase diagrams reveal how molybdenum extends beta-phase temperature ranges. This allows tailored material behavior for specific thermal cycles. Such precision enables innovations like single-crystal jet engine components.

Metallurgical Techniques for Melting Titanium

Advanced metallurgy meets extreme challenges when working with heat-resistant materials. Specialized equipment creates controlled environments to handle intense thermal demands while preventing contamination. Three primary methods dominate industrial operations, each with distinct advantages for specific applications.

Electric Arc Furnace Technology

Graphite electrodes generate temperatures exceeding 1,800°C in sealed chambers. Protective argon gas shields molten material from oxygen reactions. This method produces large ingots for aerospace components, maintaining consistent quality across batches.

Induction Heating Systems

Electromagnetic fields create rapid, uniform heating without direct contact. Precision temperature control allows for intricate casting shapes used in medical devices. Energy efficiency makes this approach popular for medium-scale production runs.

| Method | Temperature Range | Atmosphere | Applications |

|---|---|---|---|

| Electric Arc | 1,700-2,000°C | Argon/Nitrogen | Aerospace ingots |

| Induction | 1,650-1,900°C | Vacuum | Medical implants |

| Plasma Arc | 3,000-20,000°C | Inert Gas | Research alloys |

Plasma techniques utilize ionized gas streams for localized melting. This minimizes material waste during prototype development. NASA engineers employ these systems for testing advanced alloy compositions.

“Vacuum arc remelting eliminates 99.8% of impurities – crucial for turbine blades surviving Mach 3 speeds.”

Modern refinements like electron beam melting achieve purity levels above 99.95%. These processes enable next-generation applications in quantum computing components and space exploration hardware.

Comparative Analysis: Titanium vs Steel, Aluminum, and More

Selecting the right material for high-heat applications requires understanding key thermal thresholds. Engineers weigh performance against cost when choosing between industrial metals.

Temperature Benchmarks and Material Comparisons

Steel grades melt between 1,370-1,540°C – 300°C lower than titanium’s threshold. This gap matters in jet engines where components face sustained heat above 1,000°C. Steel alternatives often require cooling systems titanium-based designs avoid.

Aluminum alloys liquefy at just 660°C, limiting their use in high-temperature environments. Stainless steel performs better than standard varieties but still falls short of titanium’s thermal resilience. These differences explain why aerospace projects prioritize materials with higher heat tolerance.

Copper and nickel alloys bridge some gaps but add weight. Modern manufacturing increasingly combines metals to balance strength, cost, and temperature resistance. Each choice impacts product lifespan and safety in extreme conditions.