The density of iron is key in its many uses, like in building and making things. This article looks into iron’s properties, showing why its density matters a lot. It’s not just a number; it’s important in science and engineering.

By learning about iron metal facts, we see how its density affects its use. It’s important in both our daily lives and big industries.

What is the Density of Iron?

The density of iron is about 7.87 grams per cubic centimeter (g/cm³) at room temperature. This makes it a very dense metal. It’s perfect for many uses because it’s strong and durable.

Small changes in iron’s density can happen because of temperature or the alloy used. But, the usual density value is widely accepted in industries.

Knowing iron’s density is key in construction and manufacturing. It affects how well structures and parts work. For more on iron’s density, check out detailed guides on its properties and uses.

The density of iron is more than just a number. It affects how iron handles stress and forces. Its density helps it be used in many areas, making things work well and reliably.

How to Calculate the Density of Iron?

To find the density of iron, you need to use a specific formula. The formula is Density = Mass / Volume. This helps figure out how dense an iron sample is.

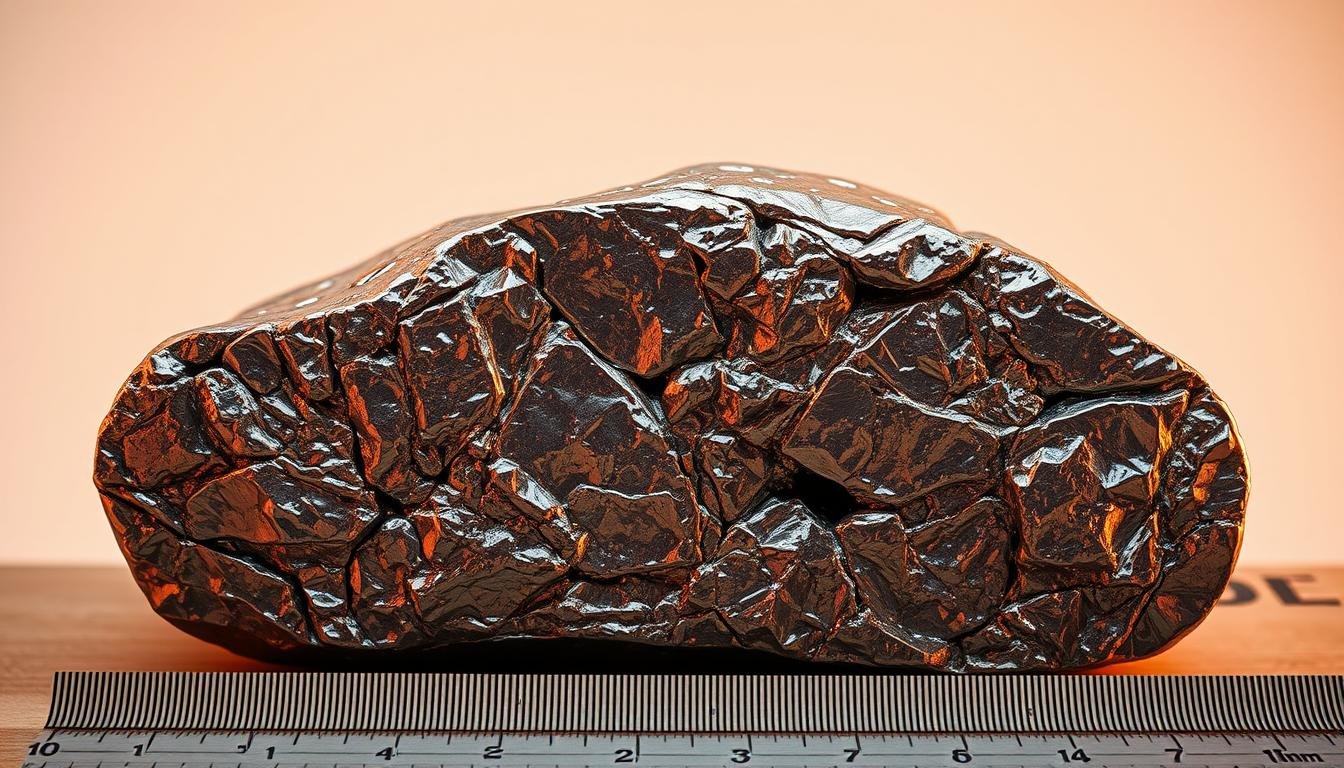

First, weigh the sample using a scale. Then, measure its volume. For shapes like cubes or cylinders, you can use simple formulas. But for irregular shapes, the water displacement method works well.

This method involves putting the sample in a graduated cylinder with water. The rise in water level shows the volume of the sample. This way, you get the volume needed.

The density of iron is about 7.87 g/cm³ at room temperature. This shows the method is accurate. By following these steps, you can better understand iron’s properties.

Why is the Density of Iron Important in Industry?

The importance of iron density in industry is huge. It helps make important choices about what materials to use and how to design things. This is true for building materials, machines, and tools.

High-density iron is loved because it’s strong and lasts a long time. This makes buildings and structures stronger. Engineers choose it because it can hold a lot of weight.

Engineers need iron density to be the same for accurate weight calculations. This is key for big projects to stay stable. It also helps save money by making production more efficient.

Knowing about iron density significance helps companies do better in their projects. It leads to better results and saves money.

| Property | Value |

|---|---|

| Iron Density at Room Temperature | 7.87 g/cm³ |

| Comparative Density (Aluminum) | 2.70 g/cm³ |

| Comparative Density (Tungsten) | 19.25 g/cm³ |

| Impact on Magnetic Properties | Influences permeability and coercivity |

| Relevance in Steel Manufacturing | Critical for strength and durability |

In summary, iron density is more than just a number. It’s about the key properties that industries need. It shapes the future of engineering and building.

Comparing the Density of Iron with Other Metals

Iron has a density of 7.87 g/cm³, making it stand out in metal density comparisons. Aluminum is much lighter, with a density of about 2.70 g/cm³. On the other hand, tungsten is very heavy, with a density of around 19.25 g/cm³. This shows how different metals are suited for different uses.

Iron’s density is just right, between aluminum’s lightness and tungsten’s heaviness. This makes iron great for many industrial tasks, like building and making things. Aluminum is perfect for when you need something light, while tungsten is best for heavy-duty jobs like shielding against radiation. Knowing these differences helps us choose the right metal for our projects.

| Metal | Density (g/cm³) | Main Applications |

|---|---|---|

| Iron | 7.87 | Construction, manufacturing, automotive |

| Aluminum | 2.70 | Aerospace, packaging, automotive |

| Tungsten | 19.25 | Radiation shielding, high-performance alloys |

How Does the Density of Iron Affect Its Properties?

The density of iron greatly affects its strength and other properties. Knowing these iron properties is key in iron material science. This is true for many industries.

Iron has a body-centered cubic (BCC) structure at room temperature. This structure makes it strong and able to handle stress well. The density effects on iron’s strength are very important. Denser atoms make the material more resistant to bending.

When iron is heated, it changes to a face-centered cubic (FCC) structure. This change makes it more ductile. It becomes easier to shape and mold, which is great for many industrial uses. The dense atomic structures are the foundation for iron alloys like steel, which mix iron with carbon for better properties.

| Iron State | Structure Type | Density (g/cm³) | Strength (MPa) | Ductility |

|---|---|---|---|---|

| Room Temperature | Body-Centered Cubic (BCC) | 7.87 | 370 | Moderate |

| Heated | Face-Centered Cubic (FCC) | 7.87 | 200 | High |

This knowledge helps engineers use iron better in engineering and manufacturing. They look at density and other properties to design the best materials. This is how iron helps make the tools and structures we use every day.

Understanding the Structure of Iron

The way iron is structured is key to its uses and qualities. At normal temperatures, iron has a body-centered cubic (BCC) arrangement. This shape helps iron be strong and flexible, making it popular in many fields.

But when iron gets hotter, its structure changes to face-centered cubic (FCC). This change makes iron better for making alloys. This ability to change shape is why iron is so useful in engineering and making steel.

Knowing how iron is structured helps us see why it’s used so much. Iron alloys have different properties, making them useful in many areas. This makes iron a valuable material in construction, manufacturing, and more.

Impact of Density on the Strength and Weight of Iron

The density strength relationship in iron is key in construction. Higher density means iron can handle more stress without bending. This is critical for building materials that need to be strong and last long.

But iron’s high density can be a problem when weight matters. For example, in aerospace, finding the right balance between strength and lightness is a big challenge. Mixing iron with other elements helps meet these needs.

For engineers and designers, knowing how iron’s density affects it is essential. They use this knowledge to pick the best materials for their projects. This way, they ensure structures are strong and don’t weigh too much.

Role of Density in Iron’s Magnetic Properties

The density of iron is key to its magnetic properties. These include how well it can carry a magnetic field and how strong it is. These traits come from how the atoms in iron are arranged and the magnetic domains they form.

Iron with a higher density has more atomic volume. This makes the magnetic domains interact more, boosting iron’s magnetism. A denser iron structure also means better magnetic flow, leading to better performance.

But, a denser iron can also have downsides. For instance, it might lose more energy when exposed to changing magnetic fields. This is important to know when making devices like transformers.

To get the best out of iron, scientists mix it with other metals. This changes its density and magnetic properties. It helps iron materials work well in many different uses.

| Property | Low Density Iron | High Density Iron |

|---|---|---|

| Permeability | Lower | Higher |

| Coercivity | Lower | Higher |

| Eddy Current Losses | Lower | Higher |

| Magnetic Domain Interaction | Weaker | Stronger |

How to Convert the Density of Iron to Different Units?

Changing the density of iron from one unit to another is key in engineering and material science. It’s vital for density conversion to be accurate. This ensures clear and consistent results in critical applications.

To switch from kg/m³ to g/cm³, it’s simple. Just divide the kg/m³ value by 1,000. For instance, iron’s density of 7,870 kg/m³ becomes 7.87 g/cm³.

Converting to lbs/ft³ is different. Multiply the kg/m³ value by 0.062428. So, iron’s density of 7,870 kg/m³ is about 491.1 lbs/ft³ through this lbs/ft³ conversion.

Knowing these conversion steps helps in accurately using iron’s density in different units. This is important for science, industry, and business.

What Are the Applications of Iron Based on Its Density?

The uses of iron are greatly influenced by its density and structure. In iron applications, the choice between pure iron and cast iron is key. Pure iron is prized for making electrical parts because it’s very ductile and magnetic.

It’s perfect for transformer cores and other electrical gadgets. Cast iron, with its strength and wear resistance, is great for industrial uses. It’s used in engine blocks and heavy machinery parts.

Cast iron also absorbs vibrations well, making it great for construction. This makes it a top choice for many structural needs.

Knowing the differences between pure iron and cast iron helps in choosing the right material. Their different densities affect how well they work in various settings. This is true from everyday use to complex industrial needs.

Density of Iron: Industrial Implications and Benefits

The density of iron is key in its use in construction. It offers many benefits, making materials more reliable and durable. High-density iron can handle big loads, which is vital for strong structures and deep foundations.

Iron’s density also helps in reducing vibrations. This is important for buildings that face dynamic loads like earthquakes or strong winds. Using iron in construction makes buildings safer and more durable.

Iron is also cost-effective, making it a top choice in many industries. Its strength, durability, and affordability are unmatched. It’s not just for construction; it also impacts the automotive and manufacturing sectors.

| Aspect | Benefits of Iron Density |

|---|---|

| Strength | Supports heavy loads in structures |

| Durability | Maintains integrity over time |

| Vibration Damping | Reduces deterioration from dynamic loads |

| Cost-Effectiveness | Affordable material for large-scale projects |

| Versatility | Applicable in multiple industrial sectors |

Conclusion

Understanding iron’s density is key to knowing its impact on materials and uses. The density of iron changes based on its structure and what’s added to it. This knowledge helps experts pick the right iron for the job, ensuring it works well and safely.

Different types of iron, like wrought and ductile, have different densities. This means engineers must think carefully about what they choose. This knowledge helps in making better materials and drives new ideas in science.

Knowing about iron’s density helps professionals make better choices. This leads to better results in projects. For more on iron and its density, check out this resource. It’s full of useful info for industry experts.