AL 6061 is a standout in aluminum alloys because of its great qualities and flexibility. This piece will explore the density specs of AL 6061 and why they matter in engineering and making things. It’s known for being tough and having excellent strength, making it a favorite in aerospace and car design.

We’ll share key insights on AL 6061’s density and its uses in real projects. This will show how knowing about AL 6061’s density is vital.

We’ll dive into the alloy’s details, like its makeup and strength. You’ll also see how it compares to other materials. This will give you a full picture of AL 6061 in today’s world. For more on its density, check out this resource.

Introduction to Aluminum Alloys

Aluminum alloys are key in many industries because they are light and versatile. They make the base metal stronger, better at conducting heat, and more resistant to rust. The choice of alloying elements is critical to their success.

Engineers use systems like the Aluminum Association’s to pick the right alloys for projects. Each group has unique properties for different uses. This careful choice is vital for top performance in tough settings.

Knowing what aluminum can do helps make smart choices for projects. They’re perfect for the aerospace and car industries because they’re efficient and long-lasting.

Understanding Aluminum 6061

Aluminum 6061 is a key part of the 6xxx series of aluminum alloys. It’s known for its magnesium and silicon content. This makes it a versatile choice for many industries.

The composition of aluminum 6061 includes about 97.9% aluminum, 0.6% silicon, and 1.0% magnesium. It also has 0.2% chromium and 0.28% copper. These elements boost the material’s strength and other properties.

Aluminum 6061 is great for welding, making it easy to shape into different parts. It’s used in construction, marine, and transportation because of its strength and lightness. Engineers and manufacturers often choose it for these reasons.

al 6061 density

The AL 6061 density values are key, at 2.7 g/cm³ (0.0975 lb/in³). These numbers are vital for engineers. They help in figuring out weight, strength, and performance in different uses.

Standard Density Values

Knowing the standard density of AL 6061 is critical. It affects weight estimates, transportation costs, and load-bearing needs. Engineers use these figures to pick the right materials for projects with tight weight limits.

Why Density Matters in Engineering

Density is very important in engineering. It shapes everything from building designs to how things are made. For example, AL 6061’s density helps ensure parts can handle stress and work efficiently.

Chemical Composition of 6061 Aluminum

Understanding the chemical makeup of 6061 aluminum is key to knowing its uses. It’s mostly aluminum, with special elements added to improve its properties.

Primary Alloying Elements

The main parts of 6061 aluminum are:

| Element | Weight Percentage (Wt. %) |

|---|---|

| Aluminum (Al) | 95.8 – 98.6 |

| Chromium (Cr) | 0.04 – 0.35 |

| Copper (Cu) | 0.15 – 0.4 |

| Iron (Fe) | Max 0.7 |

| Magnesium (Mg) | 0.8 – 1.2 |

| Manganese (Mn) | Max 0.15 |

| Silicon (Si) | 0.4 – 0.8 |

| Titanium (Ti) | Max 0.15 |

| Zinc (Zn) | Max 0.25 |

| Other, each | Max 0.05 |

| Other, total | Max 0.15 |

Effects of Composition on Density

The mix of elements in 6061 aluminum affects its density. It has a density of 2.7 g/cc, making it both light and strong. Magnesium and silicon add to its strength and protect it from corrosion. Copper, though, makes it denser and changes its ability to conduct heat and electricity.

Mechanical Properties of AL 6061

Engineers need to know the mechanical properties of AL 6061 for different uses. This aluminum alloy has both strength and flexibility. It’s good for many applications because of its yield and ultimate tensile strength.

Yield and Ultimate Strength

AL 6061 has impressive mechanical properties. It has a yield strength of 276 MPa (40,000 psi) and an ultimate tensile strength of 310 MPa (45,000 psi). This means it can handle high stress well. The alloy’s composition and tempering process affect these strengths.

Impact of Heat Treatments on Properties

Heat treatments make AL 6061 even better. The T6 temper boosts its strength and hardness. These treatments don’t change its density much. So, AL 6061 is great for projects needing strength and durability.

Corrosion Resistance of 6061 Aluminum

The corrosion resistance of 6061 aluminum is greatly improved by its natural oxide layer. This layer forms when the aluminum meets air, creating a protective shield against the environment. This is key because it stops the alloy from coming into contact with moisture or acids that could harm it.

Natural Oxide Layer Formation

The oxide layer has a special ability to heal itself when damaged. If it gets scratched or broken, the aluminum can grow back the oxide layer. This keeps its protective qualities. The environment and how long it’s exposed affect this resistance. In water or air, 6061 is very durable. But, in alkaline environments, it can be at risk of pitting corrosion, showing its limits.

Comparison with Other Alloys

In comparing alloys, 6061 stands up well against 5052. While 5052 is known for its better corrosion resistance because it doesn’t have copper, 6061 is often chosen for its mix of strength and corrosion resistance. The differences highlight the importance of picking the right alloy for each job.

| Alloy | Corrosion Resistance | Oxide Layer Properties | Applications |

|---|---|---|---|

| 6061 | Moderate | Self-healing capability | Structural components, automotive |

| 5052 | High | Excellent protective features | Marine environments, pressure vessels |

Applications of AL 6061 Aluminum

AL 6061 aluminum is used in many fields because of its versatility. It’s strong and light, making it great for many industries. These include aerospace, automotive, marine, and construction. Its unique qualities meet the needs of various applications.

Industries that Use 6061

6061 aluminum is used in several industries because of its strength and resistance to corrosion. It’s used in:

- Aerospace for aircraft frames and parts

- Automotive for truck bodies and structural parts

- Marine for boat building and frames

- Construction for scaffolding and structural elements

Specific Applications and Their Requirements

6061 aluminum meets different needs in various applications. Here are some examples:

| Application | Requirements |

|---|---|

| Welded Assemblies | High strength and excellent weldability |

| Marine Frames | Corrosion resistance and lightweight |

| Aerospace Components | High strength-to-weight ratio and durability |

| Chemical Equipment | Corrosion resistance and structural integrity |

| Furniture | Workability and aesthetic appeal |

To learn more about 6061 aluminum uses, visit this link. Its unique benefits make it perfect for high-performance and reliable applications.

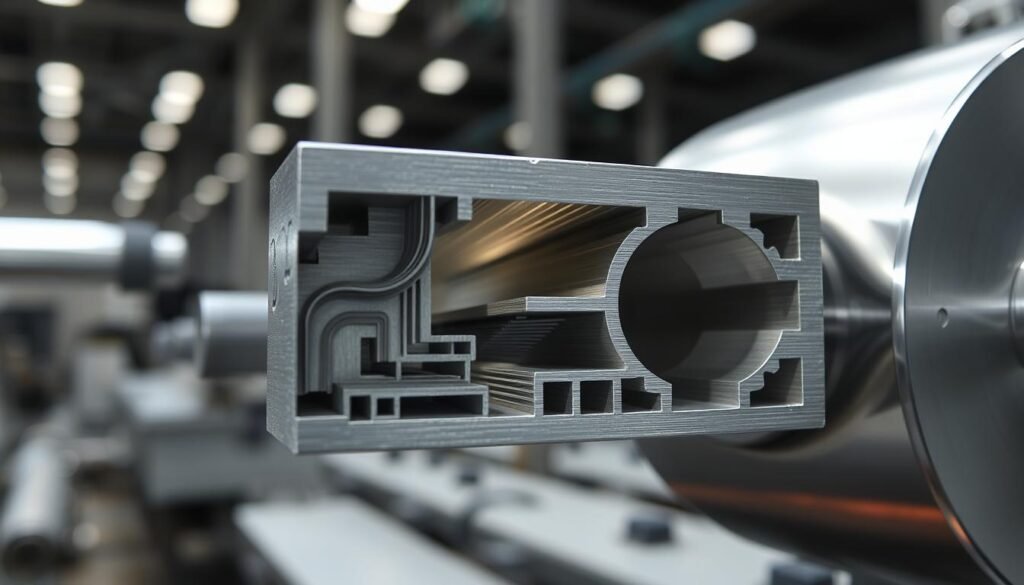

Fabrication and Machinability of AL 6061

AL 6061 is known for its great machinability. This makes it a top pick in many manufacturing areas. It can be shaped in many ways, making it versatile for different projects.

Welding Techniques Suitable for 6061

Welding is key in making AL 6061. Methods like gas tungsten arc welding (GTAW) and gas metal arc welding (GMAW) work well. Using the right filler materials, like 4043, is important for strong welds.

Forming and Finishing Processes

AL 6061 is also great for bending, stamping, and deep drawing. These processes show its strength and flexibility. Finishing with anodizing or painting adds to its look and protects it from rust. This makes AL 6061 a top choice for quality and durability.

Calculating the Weight Based on al 6061 density

Knowing how to figure out the weight of AL 6061 aluminum is key for engineers and makers. The formula for weight helps manage materials well and saves costs. The density of 6061 aluminum is about 2.7 g/cm³, making it easier to calculate.

Formula for Weight Calculation

To get the weight right, first find the object’s volume. The volume formula changes based on the shape. For example, a rectangle’s volume is length times width times height.

After finding the volume, use the density formula to get the weight. This formula is simple: Weight = Volume × Density.

Example Calculations for Common Shapes

Here are examples to show how to calculate weight for common shapes:

| Shape | Dimensions (L × W × H) | Volume (cm³) | Weight (g) |

|---|---|---|---|

| Rectangular Plate | 10 × 5 × 0.5 | 25 | 67.5 |

| Cylindrical Rod | 3 (D) × 10 (H) | 70.69 | 190.86 |

| Cube | 2 × 2 × 2 | 8 | 21.6 |

These examples show how different shapes affect volume and weight. Knowing this helps plan and use materials better in making things.

Comparing AL 6061 Density to Other Materials

Looking at AL 6061’s density, we see it’s much lighter than steel and titanium. This is key in engineering, where both strength and lightness matter. The 6061 aluminum’s lower density means big weight savings in many designs.

Density Comparisons with Steel and Titanium

Steel’s density is about 7.85 g/cm³, and titanium’s is around 4.51 g/cm³. But AL 6061’s density is just 2.70 g/cm³. This shows aluminum’s big advantage over these materials.

| Material | Density (g/cm³) |

|---|---|

| Steel | 7.85 |

| Titanium | 4.51 |

| AL 6061 | 2.70 |

Implications for Design Choices

The density implications of using AL 6061 aluminum shape product development. It lets engineers and designers make lighter, yet strong products. This opens up new possibilities in fields like aerospace and cars.

Conclusion

AL 6061 is a top choice for many reasons. It’s dense, has great mechanical properties, and resists corrosion well. It’s also versatile, making it perfect for aerospace, automotive, and construction.

Studying AL 6061 shows its big role in design and making things. Its properties help in creating new and better solutions. This knowledge helps in making designs better and pushes progress in many fields.

Using AL 6061’s special traits helps professionals make top-notch projects. This summary highlights the alloy’s key role in today’s engineering. It shows how focusing on its features can lead to better decisions and innovation.