Understanding thermal behavior is critical when working with versatile thermoplastics. Polypropylene stands out due to its balanced heat resistance, with transition temperatures between 130°C and 171°C (266°F–340°F). This range allows it to maintain structural integrity in demanding environments while remaining workable during production.

Engineers rely on this property to select materials for automotive parts, food containers, and medical devices. The plastic’s ability to soften predictably enables precise shaping through methods like injection molding. Its rigidity below the transition temperature ensures finished products withstand daily wear.

Industrial designers prioritize these thermal characteristics to optimize manufacturing efficiency. By controlling processing temperatures, they achieve consistent material flow without compromising product durability. This balance directly impacts cost-effectiveness across high-volume production lines.

Upcoming sections will explore how additives and processing techniques adjust performance thresholds. We’ll analyze real-world scenarios where slight temperature variations affect application success. Practical insights will help professionals make informed decisions for their specific needs.

Understanding the “melting point for polypropylene”: Key Factors

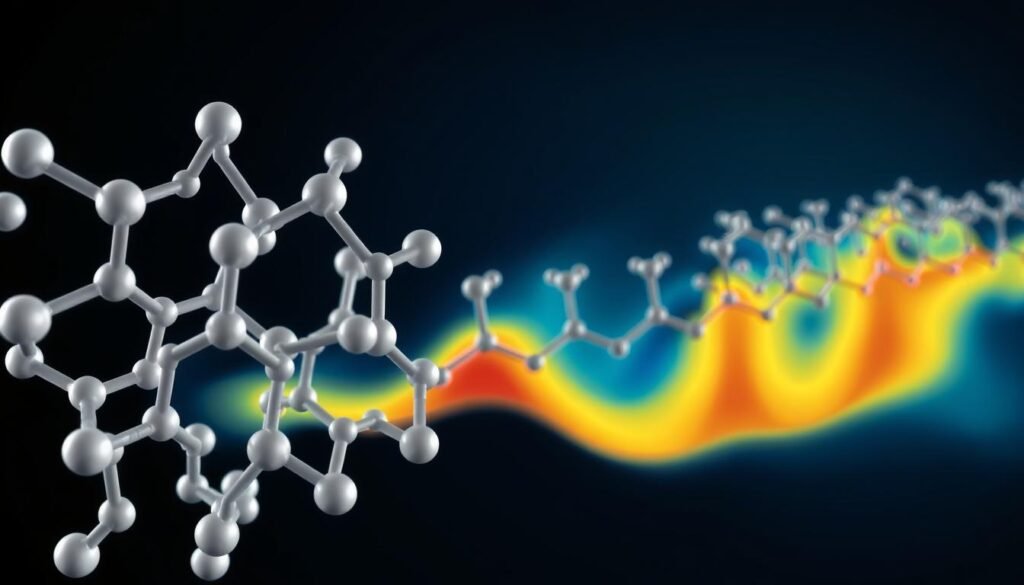

Material scientists and engineers rely on specific molecular traits to predict thermal transitions in plastics. These characteristics determine how materials perform under heat during manufacturing and use.

Molecular Weight and Crystallinity

Longer polymer chains create stronger bonds between molecules. Higher molecular weight variants require more energy to soften, enhancing their thermal stability. This makes them ideal for components needing structural integrity at elevated temperatures.

Crystalline regions in the material’s structure also play a critical role. Ordered molecular arrangements in these areas resist deformation better than amorphous sections. Products requiring rigidity often use formulations with higher crystallinity levels.

Role of Additives and Fillers

Stabilizers like phenolic antioxidants can raise a polymer’s heat resistance. For example, adding talc increases rigidity and delays softening in automotive parts. Conversely, plasticizers reduce intermolecular forces, lowering processing temperatures for thin films.

| Factor | Effect on Thermal Behavior | Application Example |

|---|---|---|

| High Molecular Weight | Increases energy needed for phase change | Industrial piping systems |

| Crystalline Structure | Boosts resistance to heat deformation | Medical sterilization containers |

| Mineral Fillers | Enhances heat deflection properties | Engine components |

By balancing these elements, manufacturers tailor materials for precise thermal requirements. This approach ensures consistent performance across injection molding, extrusion, and other processes.

How to Work with Polypropylene: A Practical How-To Guide

Precision in thermal management separates successful manufacturing outcomes from costly errors. This thermoplastic demands careful attention to phase transitions during shaping processes to maintain structural reliability.

Setting Optimal Processing Temperatures

Industrial equipment typically operates between 160°C and 170°C (320°F–338°F) for optimal material flow. Consistent thermal calibration prevents uneven melting that causes defects in molded components. Advanced monitoring systems track barrel zones to maintain ±2°C accuracy during high-volume runs.

Different polymer grades require customized profiles. High-flow variants might need 5°C reductions to prevent degradation, while reinforced compounds often demand 10°C increases for proper filler integration. Consult processing guidelines for polypropylene when adjusting parameters for specialty resins.

Ensuring Proper Cooling and Solidification

Controlled cooling rates between 20°C/min and 50°C/min optimize crystallinity development. Rapid quenching below 100°C creates amorphous regions that reduce part brittleness. Water-cooled molds achieve this effectively for thin-walled containers.

Thicker components benefit from gradual temperature drops. This approach minimizes internal stresses in automotive components while preserving dimensional stability. Always verify mold surface temperatures match material specifications before starting production cycles.

Factors Affecting Polypropylene’s Thermal Behavior

The way plastic components respond to heat depends on their microscopic design. Structural variations at the molecular level create distinct thermal profiles that determine real-world performance.

Impact of Chain Architecture on Heat Resistance

Long, tightly packed molecules resist deformation better than shorter chains. Strong van der Waals forces between these structures require substantial energy to break apart. This explains why some grades withstand temperatures exceeding 160°C without losing shape.

Three key structural elements influence thermal stability:

| Structural Feature | Thermal Impact | Application Benefit |

|---|---|---|

| Extended Chain Length | Raises energy needed for phase transition | Durable automotive parts |

| Isotactic Arrangement | Enhances crystallization potential | Sterilizable medical tools |

| Controlled Branching | Balances flexibility/stiffness ratio | Heat-resistant packaging films |

Crystalline zones act as natural reinforcement networks. Materials with 40-60% crystallinity maintain dimensional stability under prolonged heat exposure. Amorphous regions provide impact resistance but soften faster when temperatures rise.

Manufacturers adjust molecular weight distribution to optimize processing. Narrow distributions ensure uniform melting, while broader ranges improve final product toughness. Advanced polymerization techniques enable precise control over these parameters for specialized uses.

Industrial Applications and Advantages of Polypropylene

Polypropylene’s adaptability makes it indispensable in modern industry. Its ability to maintain structural strength during high-temperature processing enables efficient manufacturing across diverse sectors. From automotive systems to kitchenware, this thermoplastic delivers reliability through precise thermal management.

Injection Molding and Extrusion Processes

Manufacturers leverage injection molding to produce complex components like automotive panels and medical device housings. The material flows smoothly at 160–170°C, filling intricate molds while retaining dimensional accuracy. This process minimizes waste and supports high-volume production of identical parts.

Extrusion techniques transform polypropylene into durable pipes, packaging films, and synthetic fibers. Continuous thermal control ensures uniform thickness in products like weather-resistant construction materials. These methods prove essential for creating cost-effective solutions in infrastructure and consumer markets.

Use in Automotive and Consumer Goods

Modern vehicles contain over 100 polypropylene components, including bumpers and battery casings. Its heat resistance prevents warping in engine compartments, while lightweight properties improve fuel efficiency. Safety-tested grades meet strict industry standards for crashworthiness and chemical exposure.

Consumer products benefit from the plastic’s non-toxic nature and dishwasher-safe durability. Brands utilize it for:

- Food storage containers with leak-proof seals

- Ergonomic tool handles resistant to wear

- Child-safe toys meeting international compliance guidelines

BOYI’s advanced molding technology demonstrates how customized formulations address specific thermal and mechanical demands. Their work with automotive clients highlights polypropylene’s role in evolving electric vehicle designs.

Techniques to Modify and Lower the Melting Temperature

Industrial applications often require tailored thermal characteristics to meet specific processing demands. Engineers modify polymer behavior through strategic material combinations and structural adjustments. These techniques balance workability with performance in finished products.

Blending Methods and Copolymerization Approaches

Copolymerization introduces ethylene or other monomers into the polymer chain. This disrupts molecular alignment, reducing crystallinity by 15–40%. Ethylene-propylene copolymers maintain flexibility while lowering thermal transition thresholds by up to 30°C compared to standard grades.

Blending with materials like LDPE creates composites with intermediate properties. A 20% LDPE addition can decrease processing temperatures by 12–18°C. Manufacturers use this for thin-walled containers requiring precise molding without material degradation.

“Strategic copolymer selection allows 25% energy reduction in extrusion processes while maintaining tensile strength.”

| Method | Mechanism | Thermal Impact | Common Use |

|---|---|---|---|

| Copolymerization | Introduces ethylene monomers to disrupt molecular alignment | Reduces transition range by 20–35°C | Automotive seals, flexible packaging |

| Polymer Blending | Combines with lower-melting plastics like polystyrene | Lowers processing temps by 10–25°C | Disposable medical components |

Key considerations include maintaining chemical resistance and impact strength. Process engineers typically test multiple ratios before finalizing production parameters. Cost analysis often determines whether blending or copolymerization delivers better ROI for specific applications.

Conclusion

Mastering thermal properties ensures optimal outcomes in plastic manufacturing. The phase transition between 130°C and 171°C (266°F–340°F) defines how this thermoplastic behaves during production and use. Proper management of these temperatures maintains structural integrity while enabling efficient shaping processes.

Material selection relies heavily on understanding these thermal thresholds. Industries leverage this range to balance rigidity with adaptability, creating components for automotive systems, medical tools, and consumer goods. Precise control during molding or extrusion prevents defects and ensures consistent product quality.

Additives and copolymer blends further refine performance, as detailed in our exploration of temperature ranges of polypropylene. These adjustments allow engineers to meet specific demands without compromising durability or safety standards.

By prioritizing thermal behavior analysis, professionals achieve cost-effective solutions across sectors. This knowledge empowers smarter design choices and reinforces the material’s role in sustainable manufacturing advancements.