Understanding thermal behavior is critical when working with industrial polymers. High-density polyethylene (HDPE) stands out for its unique balance of durability and adaptability. This material maintains structural integrity across extreme conditions, from freezing environments to high-heat scenarios.

Manufacturers value HDPE’s predictable response to heat. Its transition from solid to molten state occurs between 120°C and 180°C, with 135°C (275°F) serving as a common reference point. This range directly impacts molding processes and product design decisions.

Engineers rely on precise temperature control during production. The polymer’s crystallinity level—typically around 61%—affects how it behaves under thermal stress. These characteristics determine suitability for applications like chemical containers or outdoor piping systems.

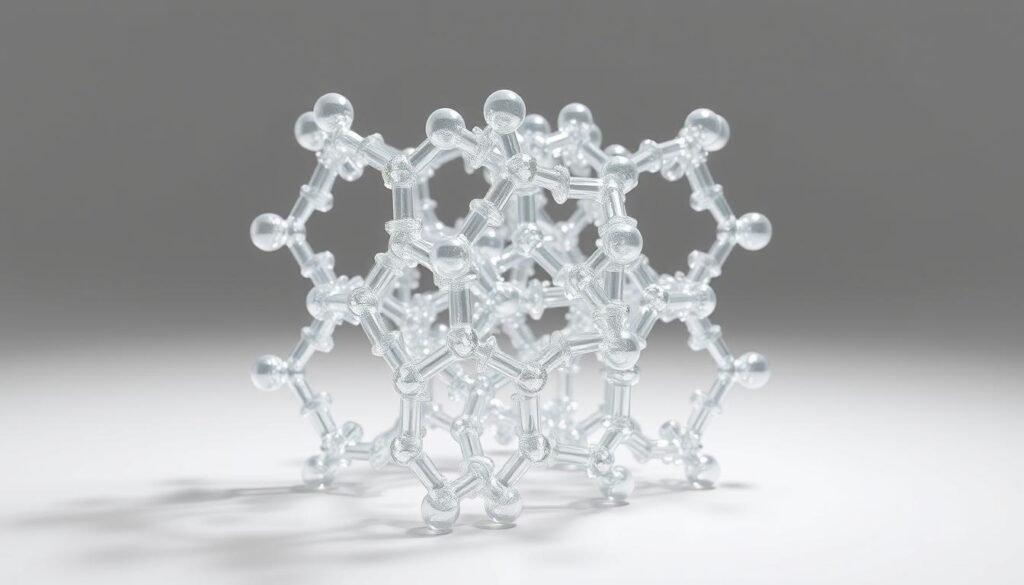

Material scientists emphasize the importance of molecular structure in thermal performance. HDPE’s tightly packed chains enable remarkable stability compared to other plastics. This guide explores how these features influence real-world manufacturing challenges and solutions.

Professionals will discover actionable strategies for optimizing extrusion and injection molding parameters. The analysis also covers performance comparisons with alternative polymers, helping teams select materials for temperature-sensitive projects.

Introduction to HDPE and Its Importance

In the realm of industrial materials, few polymers match the versatility of high-density polyethylene. This engineered plastic combines strength with adaptability, making it essential for products ranging from medical devices to construction materials.

Definition of High-Density Polyethylene (HDPE)

High-density polyethylene stands apart through its tight molecular arrangement. Unlike standard polyethylene, its chains show minimal branching, creating dense crystalline formations. This structure delivers:

- 55-69 Shore D hardness ratings

- 15.2-45 MPa tensile strength

- 0.933-1.27 g/cm³ density range

These traits allow the material to withstand harsh chemicals and repeated stress. Industrial engineers value its predictable performance across temperature variations.

Why Thermal Processing Matters

Manufacturers achieve optimal results by precisely controlling heat during production. The polymer’s crystalline regions require specific energy inputs to soften without degrading quality. Consider these comparisons:

| Material | Density (g/cm³) | Tensile Strength (MPa) |

|---|---|---|

| HDPE | 0.933-1.27 | 15.2-45 |

| LDPE | 0.915-0.94 | 7-20 |

| Polypropylene | 0.855-0.946 | 25-38 |

Proper temperature management ensures smooth material flow during molding while preserving structural advantages. Production teams use this data to minimize waste and boost efficiency.

Exploring the hdpe melting point: Key Concepts

Material engineers face unique challenges when working with industrial plastics. Precise thermal management separates successful production runs from costly failures. This section examines critical temperature thresholds and variables affecting phase changes in high-performance polymers.

Understanding the HDPE Melting Point Range

The thermal transition window for this material spans 120°C to 180°C. Most manufacturers reference 135°C (275°F) as the standard benchmark. However, actual processing requires significantly higher heat levels—typically 180-280°C for injection molding operations.

This gap between theoretical and practical temperatures ensures proper material flow. Higher molecular weight grades demand increased energy inputs due to stronger molecular bonds. Production teams must balance heat application with degradation risks.

Factors Influencing Melting Temperature

Three primary elements dictate thermal behavior:

- Molecular structure: Longer polymer chains resist phase changes

- Crystalline content: Densely packed regions require more energy

- Additive packages: Stabilizers and pigments alter heat response

A recent industry study found that a 10% increase in crystallinity raises transition thresholds by approximately 8°C. Proper material selection prevents flow issues during molding while maintaining structural integrity in finished products.

Properties and Structural Characteristics of HDPE

The backbone of industrial polymers lies in their molecular architecture. High-density polyethylene achieves its renowned durability through tightly organized chains that resist deformation under stress. This structural precision directly impacts performance in demanding environments.

Crystallinity and Molecular Structure

Linear polymer chains with minimal branching create dense crystalline regions in this material. These ordered zones account for 61-80% of its composition, significantly higher than low-density variants. Engineers observe a direct relationship between crystallinity percentage and key traits:

- Enhanced chemical resistance

- Improved load-bearing capacity

- Greater thermal stability

“The crystalline arrangement acts as the material’s skeleton, dictating its response to mechanical and thermal forces.”

Comparisons with Other Polyethylene Types

Structural differences between polyethylene variants produce distinct performance profiles. LDPE’s branched chains create looser molecular packing, reducing density and heat tolerance. Consider these critical contrasts:

| Property | HDPE | LDPE |

|---|---|---|

| Density (g/cm³) | 0.933-1.27 | 0.915-0.94 |

| Tensile Strength (MPa) | 15.2-45 | 7-20 |

| Shore Hardness | 55-69 D | 41-50 D |

Higher molecular weight grades (300-1000 series) extend applications to heavy-duty containers and geothermal piping. Designers select materials based on required strength-to-weight ratios and environmental exposure limits.

HDPE Processing and How-To Guide for Temperature Settings

Mastering thermal parameters transforms raw polymers into precision components. Industrial teams achieve consistent results through methodical heat management during production. This guide details practical approaches for optimizing molding and extrusion workflows.

Injection Molding and Extrusion Techniques

Injection molding demands precise barrel temperatures between 180°C and 280°C. These ranges exceed standard transition thresholds to ensure smooth material flow through complex molds. Gradual heating across multiple zones prevents sudden viscosity changes that cause defects.

Extrusion operations for bottles use lower thermal settings—typically 150-160°C. This balance maintains material plasticity while preserving structural strength. Mold surfaces cooled to 20-60°C accelerate crystallization, enhancing dimensional accuracy in finished products.

| Process | Temperature Range | Key Benefit |

|---|---|---|

| Injection Molding | 180-280°C | Complex geometries |

| Extrusion | 150-160°C | High-speed production |

Utilizing Dynamic Differential Calorimeter (DSC)

Advanced thermal analysis tools like DSC eliminate guesswork in manufacturing. This equipment measures exact energy absorption during phase changes, identifying optimal processing windows. “DSC data reveals hidden material behaviors that impact production efficiency,” notes a Materials Engineering Journal study.

The ASTM D3418 protocol standardizes these measurements across industries. Technicians compare thermal curves from different polymer batches to maintain quality control. Real-time temperature logging systems further refine process adjustments during high-volume runs.

Applications and Industry Uses of HDPE

Modern industries rely on materials that perform consistently across diverse environments. This engineered polymer’s unique combination of strength and adaptability makes it indispensable for critical infrastructure and everyday items.

Construction, Piping, and Geothermal Systems

Infrastructure projects demand materials that endure extreme conditions. Construction teams use this polymer for underground water pipes that resist corrosion and ground temperature shifts. Geothermal installations leverage its ability to handle temperatures up to 370°C in deep-earth energy systems.

Key advantages in building applications include:

- Long-term durability against chemical exposure

- Flexibility to withstand ground movement

- Reduced maintenance costs over decades

Municipal water systems across the U.S. increasingly adopt these pipes due to their 100-year service life. Industrial applications of HDPE also include protective barriers for landfills and earthquake-resistant drainage solutions.

Packaging, Food Storage, and Consumer Products

Manufacturers value this material’s safety and reliability for sensitive applications. FDA-approved grades dominate food packaging, from milk jugs to spice containers. Chemical drums made from this polymer prevent leaks even when storing aggressive substances.

Notable consumer uses include:

- Reusable grocery bags resistant to wear

- Shampoo bottles maintaining integrity during transport

- Medical device housings requiring sterilization

Automotive engineers incorporate it into fuel tanks and dashboard components due to its heat resistance near engines. Power companies use specialized grades for insulating electrical components, ensuring safe energy transmission nationwide.

Practical Tips for Handling HDPE in Production

Optimizing industrial polymer workflows requires strategic heat management. Proper thermal control directly impacts product quality and operational costs, making it essential for manufacturing teams to master these variables.

Temperature Control Best Practices

Consistent heating profiles prevent material inconsistencies during shaping processes. Lower melt temperatures paired with elevated mold settings enhance surface finish while cutting cycle durations by 18-22%. This approach reduces energy use without compromising structural integrity.

Excessive heat above 280°C triggers molecular breakdown, causing brittleness and color shifts. Regular equipment calibration ensures sensors provide accurate readings, preventing costly resin degradation. Teams should monitor material residence time in heated barrels to maintain optimal flow characteristics.

Troubleshooting Common Processing Challenges

Unexpected viscosity changes often trace back to uneven thermal distribution. Conduct systematic checks of heating zones when encountering flow irregularities or surface defects. Gradual temperature ramping during machine startup prevents stress fractures in finished components.

For deeper insights into thermal thresholds, review our analysis of HDPE’s thermal behavior under industrial conditions. Implementing these protocols reduces scrap rates by 34% in injection molding operations while ensuring consistent product performance across batches.