Swiss CNC Machining Materials

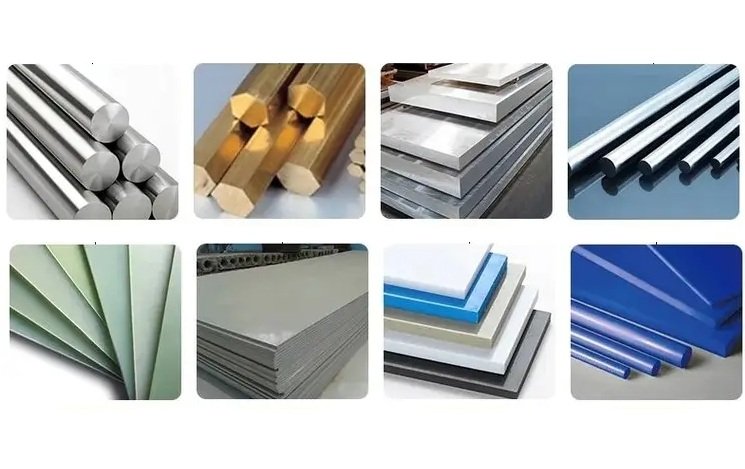

Complete Range of Precision Materials for Swiss Turning Applications

Swisscncshop offers an extensive selection of high-quality metals, alloys, and engineering plastics specifically chosen for Swiss CNC machining. From aerospace-grade aluminum to medical-grade PEEK, we provide materials that meet the most demanding precision requirements.

Material Categories Overview

Our comprehensive material library includes over 50 different grades of metals, alloys, and engineering plastics, each selected for optimal Swiss machining performance and precision applications.

Metal Alloys

Aluminum, stainless steel, carbon steel, tool steel, and specialty alloys for demanding applications.

Engineering Plastics

High-performance polymers including PEEK, POM, PTFE, and medical-grade materials.

Specialty Materials

Titanium, brass, copper, bronze, and exotic alloys for specialized applications.

Detailed Material Specifications

Metal Alloys – Swiss Machining Grades

| Material | Grade/Alloy | Properties | Applications | Machinability |

|---|---|---|---|---|

| Aluminum | 6061-T6 | Excellent strength-to-weight ratio, corrosion resistant | Aerospace, automotive, general fabrication | Excellent |

| Aluminum | 7075-T6 | High strength aluminum, excellent fatigue resistance | Aircraft structures, high-stress components | Good |

| Aluminum | 2024-T4 | High strength, poor corrosion resistance | Fasteners, fittings, automotive parts | Excellent |

| Stainless Steel | 303 | Free machining, good corrosion resistance | Screws, bolts, nuts, shafts | Excellent |

| Stainless Steel | 316L | Superior corrosion resistance, medical grade | Medical devices, marine applications | Good |

| Carbon Steel | 1018 | Low carbon, high ductility, weldable | General machinery, structural components | Excellent |

| Tool Steel | A2 | Air hardening, wear resistant | Dies, punches, cutting tools | Moderate |

| Titanium | Ti-6Al-4V | High strength, biocompatible, corrosion resistant | Medical implants, aerospace components | Challenging |

Engineering Plastics – Precision Grades

| Material | Grade | Key Properties | Applications | Temperature Range |

|---|---|---|---|---|

| PEEK | Natural/450G | High temp resistance, chemical inert, biocompatible | Medical implants, aerospace bearings | -60°C to +250°C |

| POM (Delrin) | Acetal Copolymer | Low friction, high strength, dimensional stability | Gears, bearings, automotive parts | -40°C to +100°C |

| PTFE | Virgin/Teflon | Non-stick, chemical resistant, low friction | Seals, gaskets, chemical processing | -200°C to +260°C |

| Nylon | PA6/PA66 | High strength, wear resistant, self-lubricating | Bushings, washers, mechanical parts | -30°C to +120°C |

| UHMWPE | Ultra High MW | Extremely wear resistant, low friction | Medical implants, wear plates | -200°C to +80°C |

| PMMA | Acrylic | Optical clarity, UV resistant | Optical components, lenses | -40°C to +70°C |

Specialty Alloys & Non-Ferrous Metals

| Material | Grade | Characteristics | Applications | Cost Level |

|---|---|---|---|---|

| Brass | 360 Free Machining | Excellent machinability, corrosion resistant | Valves, fittings, electrical components | $ |

| Copper | C101 OFHC | High conductivity, antimicrobial | Electrical contacts, heat exchangers | $$ |

| Bronze | 932 Bearing Bronze | Self-lubricating, wear resistant | Bushings, bearings, marine hardware | $$ |

| Inconel | 718 | High temp strength, oxidation resistant | Gas turbines, aerospace applications | $$$$ |

| Hastelloy | C-276 | Superior corrosion resistance | Chemical processing, nuclear | $$$$ |

Material Selection Expertise

Choosing the right material for Swiss CNC machining requires understanding the unique demands of your application. Our materials engineers work with you to optimize material selection based on:

Mechanical Properties

Strength, hardness, ductility, and fatigue resistance requirements

Environmental Conditions

Temperature, corrosion, chemical exposure, and wear resistance

Manufacturing Requirements

Tolerances, surface finish, secondary operations, and volume

Regulatory Compliance

FDA, REACH, RoHS, and industry-specific certifications

Industry Applications & Material Pairings

Medical & Dental

Aerospace

Automotive

Electronics

Industrial

Chemical

Quality Assurance & Certifications

Every material in our inventory meets stringent quality standards and comes with full traceability documentation. Our quality management system ensures consistent material properties and performance.

Material Certifications

- • Mill Test Certificates

- • Chemical Analysis Reports

- • Mechanical Property Testing

- • Dimensional Verification

Quality Standards

- • ISO 9001:2015 Certified

- • AS9100D Aerospace

- • ISO 13485 Medical

- • IATF 16949 Automotive

Testing Capabilities

- • CMM Dimensional Inspection

- • Surface Roughness Testing

- • Hardness Verification

- • Material Composition Analysis

Traceability

- • Full Material Genealogy

- • Batch/Lot Tracking

- • Process Documentation

- • Compliance Reporting

Why Choose Swisscncshop for Your Materials

As a leading Chinese manufacturer with global quality standards, we combine cost-effective sourcing with rigorous quality control to deliver materials that meet your exact specifications.

Extensive Inventory

50+ material grades in stock with fast delivery worldwide

Cost Advantage

30-50% cost savings compared to Western suppliers

Global Standards

ISO certified with full material documentation

Expert Support

24/7 materials engineering consultation available

Get Your Material Quote Today

Ready to source the perfect materials for your Swiss CNC machining project? Our materials experts are standing by to help you select the optimal grade and provide competitive pricing.