6061 T6 aluminum is a well-known alloy. It’s known for its great versatility and strength. It has a unique mix of properties, including a high density, making it a top pick for many fields.

These fields include construction, aerospace, automotive, and marine. The alloy’s strong resistance to corrosion is a big reason for its popularity. We’ll dive into the details of this alloy, focusing on its density and material properties. We’ll use reliable sources like the Aluminum Association for this information.

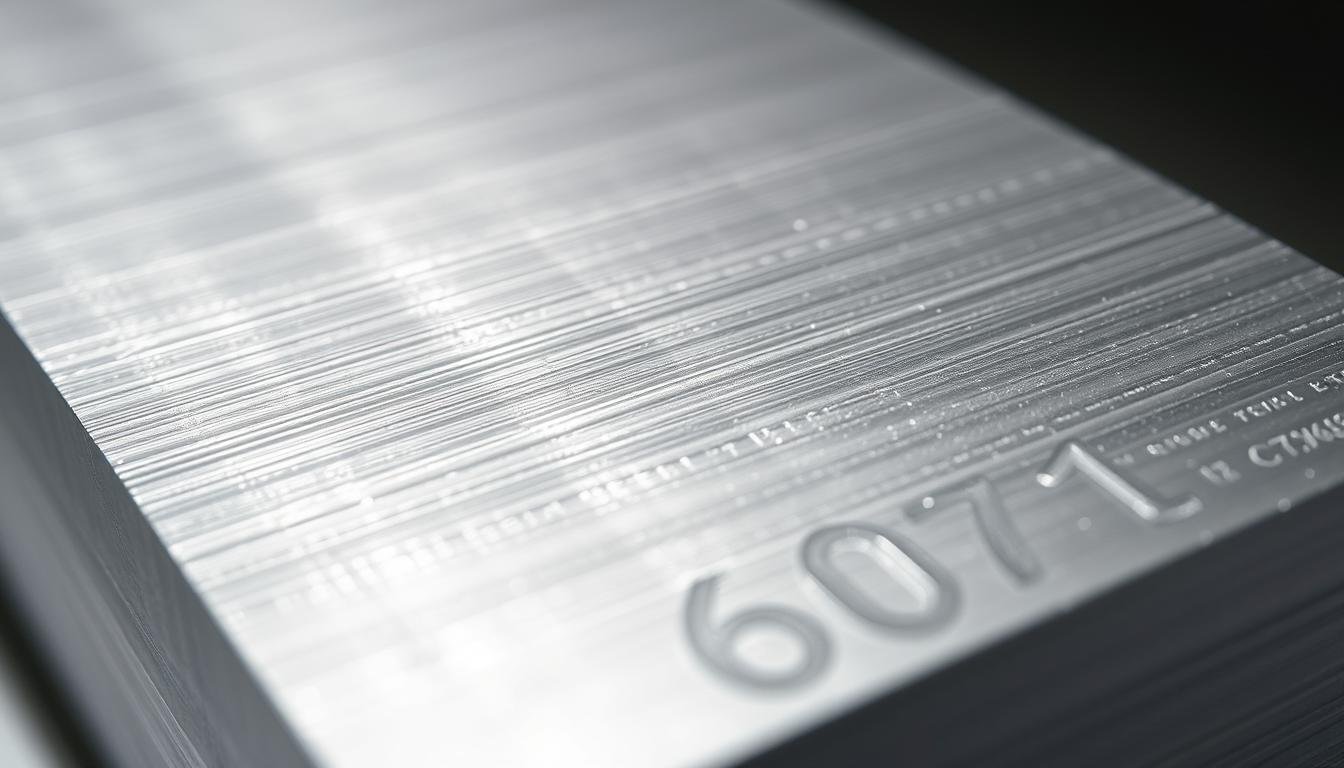

Introduction to 6061 T6 Aluminum

6061 T6 aluminum is part of the 6000 series of aluminum alloys. It’s known for its great mechanical properties and versatility. Developed in 1935, this alloy is famous for its strength, thanks to the T6 temper.

The introduction to 6061 T6 aluminum shows its big role in many industries. It’s great for making complex shapes and strong parts. The aerospace and automotive fields love it for its unique qualities.

Among aluminum alloys, 6061 T6 stands out for being easy to weld. It’s perfect for projects needing strong yet light materials. Knowing its benefits helps engineers and designers choose the right materials for their projects.

What is 6061 T6 Aluminum?

6061 T6 aluminum is a strong and durable alloy. It’s made mostly of aluminum (95.8-98.6%), magnesium (0.8-1.2%), and silicon (0.4-0.8%). This mix gives it special properties of 6061 T6 aluminum, making it great for many uses.

The T6 temper makes this alloy even stronger. This is why it’s often used in tough projects. It’s light but also very strong, which is why many industries choose it.

When it comes to fighting corrosion, 6061 T6 aluminum is a top performer. It stays strong even in harsh conditions, which means less upkeep. The aluminum alloy definition also shows it’s easy to work with. This makes it useful in many fields.

Chemical Composition of 6061 T6 Aluminum

The chemical makeup of 6061 T6 aluminum is key to knowing its uses and benefits. It mainly has aluminum, making up 95.8% to 98.6%. Magnesium is also important, with 0.8% to 1.2% in the mix. Silicon adds to the alloy, ranging from 0.4% to 0.8%.

Smaller amounts of copper (0.15% to 0.4%) and chromium (0.04% to 0.35%) also play a role. These elements together make 6061 T6 aluminum strong and easy to work with. The exact mix of these materials makes the alloy great for many uses, from building to space travel.

Knowing the exact chemical makeup helps engineers and designers. It lets them make the best choices for their projects. This ensures they get the results they need.

| Element | Percentage Range (%) |

|---|---|

| Aluminum | 95.8 – 98.6 |

| Magnesium | 0.8 – 1.2 |

| Silicon | 0.4 – 0.8 |

| Copper | 0.15 – 0.4 |

| Chromium | 0.04 – 0.35 |

Physical Properties of 6061 T6 Aluminum

The physical properties of 6061 T6 aluminum make it very popular in many industries. It has a density of about 2.7 g/cm³ (0.0975 lb/in³). This makes it strong yet light, perfect for building things.

It also doesn’t corrode easily, which means it lasts long in tough conditions. This is why many makers choose it for their projects.

When it comes to heat, 6061 T6 aluminum does well. It can handle heat well, thanks to its thermal conductivity of about 167 W/m-K. It also melts between 582 to 652°C (1080 to 1205°F). This is important for high-temperature work.

The material is also quite hard, with a Brinell hardness of about 95. This makes it strong and good for many uses. People who design and build things like this alloy because it’s strong, efficient with heat, and lasts a long time.

6061 T6 Density

The density of 6061 T6 aluminum is key in its use in engineering. Knowing its density helps choose the right material for different needs. It has a density of about 2.7 g/cm³ (0.0975 lb/in³). This makes it strong yet light, perfect for designs that need to be both durable and not too heavy.

Understanding Density Measurements

Density measurements are vital for engineering projects. They affect how much something weighs and its strength. The density of 6061 T6 aluminum is important for designing. It helps predict how well a material will perform, which is critical in areas like aerospace where saving fuel is important.

How Density Affects Material Performance

Choosing the right density is key to a material’s performance. For 6061 T6 aluminum, its low density makes it strong under stress. This means structures made from it can last longer and work better. Engineers look at this when picking materials for their projects.

Mechanical Properties of 6061 T6 Aluminum

The mechanical properties of 6061 T6 aluminum are key to understanding its performance. This alloy is known for its strong properties, making it great for building things. Its tensile and fatigue strength are important for engineering and design.

Tensile Strength and Yield Strength

The ultimate tensile strength of 6061 T6 aluminum is about 310 MPa (45,000 psi). This shows the material can handle a lot of stress before it starts to bend. The yield strength of 276 MPa (40,000 psi) also shows it can keep its shape under weight.

Fatigue Strength and Elongation

The fatigue strength of 6061 T6 aluminum is near 96.5 MPa (14,000 psi). This is good for things that are used a lot and need to last. The material can stretch up to 17% without breaking, showing it’s flexible.

Thermal and Electrical Properties

6061 T6 aluminum has great thermal properties, making it perfect for many uses. It can transfer heat well, thanks to its thermal conductivity of about 167 W/m-K. This is key for applications that need to get rid of heat efficiently.

The material also expands about 23.6 µm/m-°C with temperature changes. This is important for parts that face temperature swings.

When it comes to electricity, 6061 T6 aluminum is a standout. It has a resistivity of 3.99 × 10⁻⁶ ohm-cm, showing it’s very good at conducting electricity. This is great for making electrical parts that need to work well.

Its ability to handle heat and electricity makes it useful in many areas. It’s great for heat exchangers and electrical housings, showing its wide range of uses.

Applications of 6061 T6 Aluminum

6061 T6 aluminum is widely used in many fields. It’s known for its strength, durability, and resistance to corrosion. This makes it a top choice for both building and transportation needs.

Common Uses in Construction and Aerospace

In construction, 6061 T6 aluminum is prized for being light yet strong. It’s used in many ways, like:

- Aircraft fittings

- Marine hardware

- Structural components

The aerospace field also relies on it a lot. It’s used in:

- Fuselage structures

- Wing components of homebuilt aircraft

Automotive and Marine Applications

In cars, 6061 T6 aluminum is key for:

- Chassis construction

- High-performance components like bike frames

- Automotive parts such as the chassis of luxury models like the Audi A8

At sea, it’s used in:

- Small utility boats

- Various fittings

Fabrication Techniques for 6061 T6 Aluminum

The fabrication of 6061 T6 aluminum offers many benefits. It’s a favorite in many fields because of its precision and versatility. Techniques like machining, welding, bending, and extrusion help make complex parts.

Its excellent machinability, in T4 and T6 tempers, makes shaping easy. This means it can be molded into detailed structures.

Welding methods, like TIG and MIG, are great for joining parts. Even though welding changes the alloy’s heat-treated properties, treatments can fix this. This makes it perfect for projects needing strong structures.

Cold forming and hot stamping also boost 6061 T6 aluminum’s manufacturing abilities. These methods allow for detailed designs. This makes it a top choice for complex parts in many industries.

Advantages and Disadvantages of Using 6061 T6 Aluminum

6061 T6 aluminum is popular for many reasons. It’s strong yet light, making it great for building things. It also doesn’t rust easily, which is good for outdoor use. This makes it a top pick for construction and aerospace.

It’s also easy to work with, thanks to its good machinability. You can weld it well with the right method. Plus, it comes in many forms to fit different needs.

But, it’s not perfect. It’s not as strong in shear or fatigue as some other alloys. This can be a problem in high-stress situations. Knowing the pros and cons of 6061 T6 can help you understand these issues better.

Conclusion

6061 T6 aluminum is a top choice for many industries like aerospace, automotive, and construction. It has a reliable density, strong mechanical properties, and good heat transfer. This makes it very useful in today’s projects.

When picking materials, knowing about 6061 T6 aluminum’s properties is key. It affects how well a design works and how efficient it is. This is important for engineers and designers.

Looking at the material’s properties, like tensile and yield strength, shows its value. It’s great for building strong parts and frameworks. Its ability to be shaped in different ways also makes it popular.

Choosing 6061 T6 aluminum can lead to better and more durable projects. Learning more about it, like from this detailed guide, helps make better decisions. It’s a smart choice for many applications.